Single Phase Mini CNC Press Brake for Home-Use

Customizable

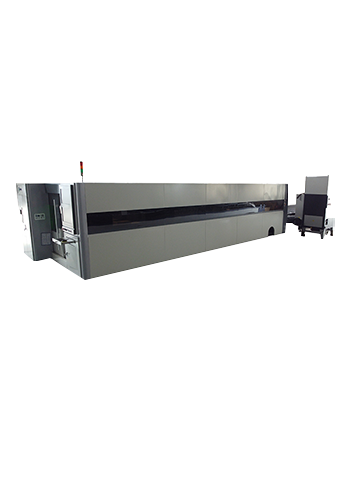

Customization Options for the Laser Machine

- Customizable 1

Custom Laser Machine Models

Start with a standard fiber laser cutter and customize the specifications to fit your unique requirements.

- Customizable 2

Size Customization

We provide customized laser cutting machine sizes and power to adapt to the plate processing of different products. The following are our Conventional laser machine size and power.

| Model | Overall dimensions | Laser output power |

|---|---|---|

| RWLG-3015G | 4600*2750*1750 | 500W---2000W |

| RWLG-4015G | 5600*2750*1750 | 500W---2000W |

| RWLG-6015G | 7600*2750*1750 | 500W---2000W |

| RWLG-6020G | 7600*3250*1750 | 500W---2000W |

Pleasecontact usfor more customized sizes.

- Customizable 3

Customized Laser Head

We offer customizable Laser Head-Bochu:Plane Groove BLT4X1, Flat BLT6X2H, Variable Beam Butting Head BLT8XOH, Flat Weld Pool BLT6X2M, Pipe Cutting BLT4X1T

BLT4X1

BLT6X2H

BLT8XOH

BLT6X2M

BLT4X1T

- Customizable 4

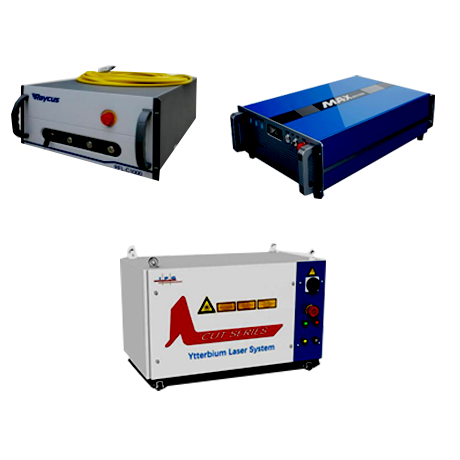

Laser Source Configuration

1. High beam quality output.

2. High reliability, long service life.

3. Can use air cutting to save costs.

4. High electro-optical conversion efficiency.

5. Compact design.

6. Optical output comes with a collimation output.

7. external computer controlinterface.

- Customizable 5

Automatic lubrication system Configuration

Automatic lubrication system for Liner guide and Rack and pinion.which can easily lubricate smoothly and automatically, so that can ensure flexibility and stably of transmission system . Free maintenance and extend the lifetime of working tables.

Laser Cutting Machine Customization Process

Step by step, we ensure your machine meets your exact needs.Requirement Analysis

Tell us your material, thickness, and cutting needs.

We help you select the right laser power, machine size, and configuration to match your production requirements.

Design & Quotation

We design a tailored solution based on your requirements.

You receive a clear quotation with machine specifications, ensuring transparency and no hidden costs.

Sample Confirmation

We provide free sample cutting tests.

You can check cutting precision, edge quality, and efficiency before confirming your order.

Production

Manufacturing begins once the design is approved.

We use strict quality control processes to ensure every component meets international standards.

Inspection & Shipping

Every machine is tested before delivery.

We guarantee stable performance, safe packaging, and on-time shipment to your location.

Installation & Lifetime Support

Our engineers provide installation guidance and training.

You benefit from global after-sales service, spare parts supply, and lifetime technical support.

Customized Laser Machine Service Advantages

Professional Customization Capability

Laser machine's custom capabilities have perks. Starting with customer research on material, accuracy, and appearance, the design team uses CAD/CAM for modeling and path planning. In production, parameters are adjusted and exclusive fixtures made. Quality control uses high-precision equipment to meet customer needs in multiple fields.

High Cost-effectiveness

Laser machines have high cost performance. The purchase cost is competitive considering long-term stable operation and low maintenance despite a relatively high initial investment. In terms of efficiency, advanced laser tech enables high-speed, precise processing, shortening production time and reducing labor costs. Also, they adapt well to various materials, reducing losses and bringing economic benefits for cost reduction and efficiency gain.

Close Collaboration with Customers

Laser machine manufacturers focus on close cooperation with customers. Pre-sales, they understand needs, goals and difficulties through communication and offer accurate selection suggestions. During sales, technicians follow installation and commissioning and train operators. After-sales, stable channels are built to respond timely, arrange experts for any feedback to optimize solutions and boost customers' production efficiency.

High Quality Assurance

The laser machine has a high-quality guarantee system. When designing, it uses advanced tech & software to optimize structure & optical path, sets parameters per industry standards. For procurement, it strictly chooses suppliers and samples materials. In production, it follows the process, relying on automated line for precise operation with detection points. Finished products are checked by high-precision equipment and only leave factory when meeting standards to meet strict requirements.

Technical Innovation and Upgrades

Laser machines keep innovating. In laser source tech, develop high-power, stable lasers for precise beam control and material range expansion, solving hard-to-process issues. Intelligent control system uses algorithms to auto-optimize parameters and adjust the path based on material and process for better precision and efficiency. Mechanical structure employs lightweight, rigid materials and optimizes layout for enhanced stability and portability. Integrated with IoT for remote monitoring and diagnosis to boost laser machine performance and meet new industrial needs.

Comprehensive After-sales Service

Laser after-sales eases concerns. 24h hotline gets techs for remote help. Local stations with parts for quick repairs. Trainings unlock potential, extend life. Feedback optimizes service.

Frequently Asked Questions

- What does the after-sales service of laser machines include?Laser machine uses laser to generate high-energy focused laser beam, which acts on materials through optical elements, and realizes various processing by thermal effect and photochemical effect. It has the advantages of high precision, high energy density, non-contact, wide processing material range, easy automation, etc., and is widely used in manufacturing, electronics industry, medical treatment, communications and other fields.

- What is the processing accuracy of laser machining?Equipped with the most advanced international imported fiber laser source which generates powerful laser focused on objects to cause instant melting and evaporation.Automatic cutting is controlled by digitalied mechanic system.This hi-tech machine has condensed the advanced technologies of fiber laser,digital,and precise mechanics. Applicable to fast cutting on plate or tube in metal,mainly for cutting on SS,carbon steel,Manganese steel ,galvanized plate,alloy plate,rare meta.

- What materials can laser machines process?Equipped with the most advanced international imported fiber laser source which generates powerful laser focused on objects to cause instant melting and evaporation.Automatic cutting is controlled by digitalied mechanic system.This hi-tech machine has condensed the advanced technologies of fiber laser,digital,and precise mechanics.

- How to choose the laser machine power?Laser machine: Power - low (20W - 100W for engraving), medium (300W - 1000W for cutting/welding), high (1000W+ for heavy work); Processes metal/non-metal. Engraving accuracy micron, cutting accuracy mm-submm. Normal maintenance: Laser 20,000 - 50,000 hrs, machine 10 - 15 yrs. Novices master basics in 1 - 3 days.

Start Customizing

Customized Laser Cutting Machine Quick Quote

- Press Brake

- Laser Cutting Machine

- Shearing Machine

- Plate Bending Machine

- Quick Quotation

- Phone

- Phone

- Phone

- Phone

- Phone

Download Product Operation Manuals

Installation and Commissioning Guidance

Equipment Maintenance Training

Sample Support for Equipment Spare Parts

Support for Third-party Factory Inspections

Free Technical Consultation Services

Join Our Distributors

- Phone

- *Title

- *Content