Single Phase Mini CNC Press Brake for Home-Use

File cabinets Manufacturing Industry Solutions

Solutions

Challenges Facing the Filing Cabinet Manufacturing Industry

Low machining accuracy

- Traditional production usually relies on manual operation or old-fashioned mechanical equipment, such as manual cutting, stamping, manual bending, etc., with low precision and large errors.

- The individual parts of the filing cabinet may have dimensional deviations due to improper operation or aging equipment, affecting the overall assembly and aesthetics.

Low production efficiency

- The individual parts of the filing cabinet need to be manually machined, adjusted and trimmed, and the human factor in the operation process can lead to slower production speeds.

- Manual adjustment of machinery and equipment and tools consumes a lot of time, especially in mass production, and the efficiency is not as good as that of high-precision machines.

High production costs

- The initial investment of traditional production is low, but there is more labor dependence, low production efficiency, and high material waste and quality control problems.

- In the production process, manual handling errors and the frequency of process adjustments can lead to higher costs

Low material utilization

- Limited capacity for independent R&D and innovation makes it difficult to launch competitive new products.

- Difficulty in achieving efficient material placement and cutting can lead to unnecessary waste and impact production costs

MetalWorkMaster Solutions for Filing Cabinet Manufacturing

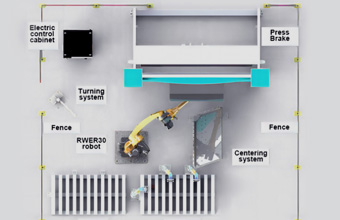

Providing Efficient, Smart Machine Tools

By introducing automation and intelligent technologies, we can achieve automation and intelligent management of production processes, reduce manual intervention, and improve production efficiency and product quality.

Enhancing Quality Control and Precision Management

We provide high-precision, consistent machine tools to ensure accuracy and uniformity in file cabinets manufacturing. By integrating advanced inspection technology and a comprehensive quality management system, we rigorously control every step of the production process, guaranteeing reliable and stable product quality.

Precision

Our equipment is designed with high machining precision to meet the exact dimensional and shape requirements for file cabinets panels.

Stability

Equipment operates with high stability, ensuring continuity and consistency in the production process.

Adaptability

Machines are adaptable to different file cabinets panel specifications and materials, providing flexibility and versatility.

Automation Level

Higher automation levels improve production efficiency and maintain quality consistency.

Optimizing Cost Control and Energy Management

Our machine tools are designed to be efficient and energy-saving, helping to significantly reduce costs in materials, labor, and energy consumption. By optimizing production processes and designs, we enable economies of scale and cost control, improving overall profitability.

Driving Technological Innovation and Industry Upgrades

We continue to invest in R&D and innovation, launching new products and technologies with independent intellectual property rights to meet the changing needs of the market.

We cooperate with universities, scientific research institutions, etc. to jointly carry out technological R&D and innovation to promote the industrial upgrading and sustainable development of the File cabinets manufacturing industry.

Filing Cabinet Production Line Solution

Production Line for Filing Cabinet Manufacturing

Punch Press

Spray Paint Machine

Filing Cabinet

Start Customizing

Customization of Sheet Metal Equipment for File cabinets Manufacturing

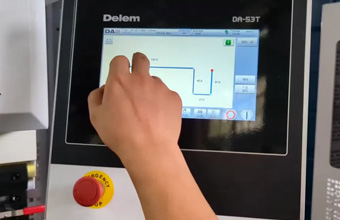

File cabinets ProcessingPress Brake

It is used to bend metal sheets according to design requirements to produce the shapes of various parts of file cabinets.

Choose the right type of press brake according to your specific needs: torsion bar series, electro-hydraulic synchronous series, all-electric series, tandem press brake, panel press brake

Press Brake Customization

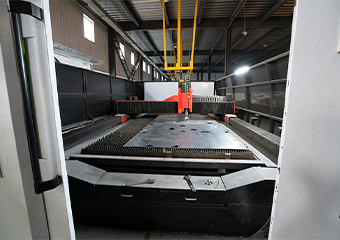

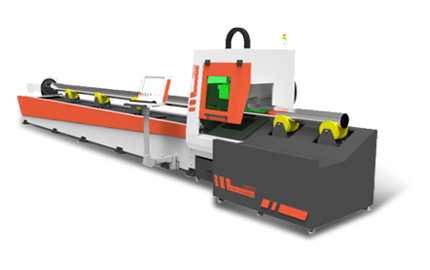

File cabinets ProcessingLaser Machine

Used to cut metal sheets to make file cabinets frames and other parts.

Laser Machine Customization

File cabinets ProcessingShearing Machine

Used to cut metal sheets according to the designed size to ensure the accuracy of the sheet size.

Shearing Machine Customization

File cabinets ProcessingPlate Rolling Machine

Used to cut metal sheets to make file cabinets frames and other parts.

Plate Rolling Machine CustomizationSuccessful Cases

Brazilian customer

The metalworking equipment manufacturer offers extremely high precision and minimal dimensional deviations when machining metal components, which greatly improves the quality and stability of the products.

Indonesian customer

MeteWorkMaster's metalworking equipment runs very smoothly and works continuously for long periods of time without breakdowns, and is extremely reliable. The versatility of the machine is also impressive, and it can easily cope with metalworking tasks with complex shapesur production efficiency

Indian customer

The price of MeteWorkMaster's equipment is reasonable, and the upfront investment does not cause us too much financial pressure. Moreover, the operation of the equipment is simple and easy to learn, and new employees can become proficient in operation after a short period of training.

Contact MetalWorkMaster

Need Assistance?

Download Product Operation Manuals

Installation and Commissioning Guidance

Equipment Maintenance Training

Sample Support for Equipment Spare Parts

Support for Third-party Factory Inspections

Free Technical Consultation Services

Consult Sheet Metal Equipment Experts

- Quick Quotation

- Phone

Join Our Distributors

- Phone

- *Title

- *Content