Single Phase Mini CNC Press Brake for Home-Use

Empower Legacy Equipment. Unlock a Smarter Tomorrow.

Are these issues happening in your factory?

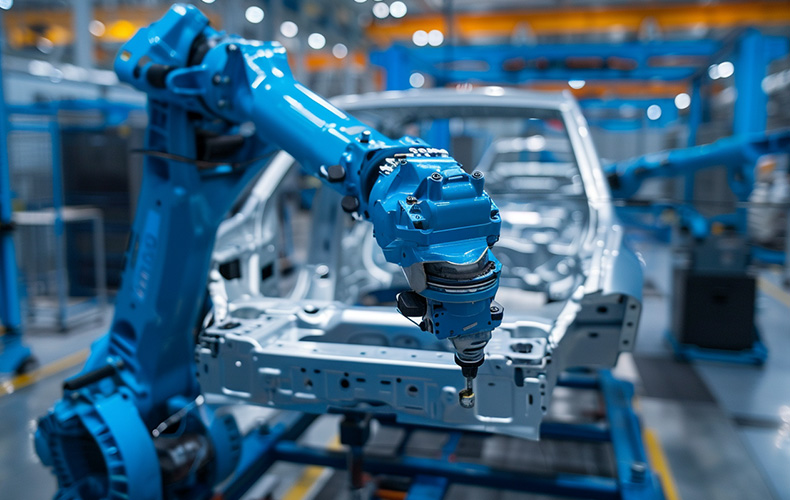

One Upgrade Can Transform Your Entire Factory

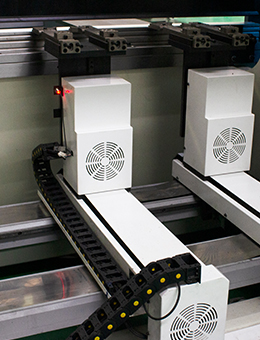

PLC & Multi-Axis Controller Upgrades

Replace outdated PLCs with smart controllers to achieve higher automation and precision.

AI Vision & Auto Compensation

Integrate AI cameras to detect position deviations and auto-adjust in real time.

Remote Monitoring & IoT Connectivity

Enable real-time remote access and alerts via cloud dashboards or mobile apps.

Servo-Hydraulic Energy Retrofit

Upgrade to eco-efficient systems to cut energy costs and improve performance.

Line Reconfiguration & Flexibility Upgrade

Redesign machine layout for greater adaptability and reduced changeover time.

Custom Retrofit Plans + Long-Term Support

Dedicated consultants guide your upgrade journey — with full lifecycle support.

Before & After: Real Client Transformation Stories

Just Six Steps to Smarter Equipment Upgrades

Needs Assessment

Our consultants conduct a 1-on-1 discussion to understand your production goals and current machine limitations.

On-Site Audit

Our engineers inspect your machines on-site, collect technical data, and assess upgrade feasibility.

Custom Retrofit Proposal

We deliver a tailored plan with schematic drawings, BOM, timeline, and budget to match your needs.

Retrofit Execution

Our team implements hardware and software upgrades including controls, hydraulics, and mechanical mods.

Commissioning & Integration

We test system performance, tune parameters, and integrate with your existing workflow or MES.

Training & Remote Support

We train your team, install remote service modules, and enable continuous after-sales support.

Not Just Machines — We Understand Transformation

- In-Depth Equipment Understanding

15+ years of in-house machine building means faster upgrades and perfect hardware compatibility.

- Full-Stack Technical Expertise

From controls and hydraulics to AI and IoT — all upgrades are fully integrated under one roof.

- Automotive Plastics

Clients in 150+ countries trust our solutions — with remote support and local delivery options.

- Measurable ROI Focus

25% average energy savings, 30% productivity gain, ROI within 12 months — proven numbers, every time.

Frequently Asked Questions

- Are CNC bending machines always better than manual bending machines?CNC automation can significantly improve machining accuracy and efficiency, easily handling the manufacturing of complex parts; however, in applications with small batches, low precision, or limited budgets, manual bending machines remain a cost-effective choice.

- Can the press brake be customized to specific requirements?Yes, we provide customization options, including different sizes, control systems, and additional features to meet specific industrial needs.

- Do you handle customs clearance for international shipments?Yes, we assist with customs clearance for international shipments, ensuring all necessary documentation is provided and the process is handled efficiently to avoid delays.

- What materials can laser machines process?Equipped with the most advanced international imported fiber laser source which generates powerful laser focused on objects to cause instant melting and evaporation.Automatic cutting is controlled by digitalied mechanic system.This hi-tech machine has condensed the advanced technologies of fiber laser,digital,and precise mechanics.

Start Customizing

Customized Bending Machine Quick Quote

- Press Brake

- Laser Cutting Machine

- Shearing Machine

- Plate Bending Machine

- Quick Quotation

- Phone

- Phone

- Phone

- Phone

- Phone

Join Our Distributors

- Phone

- *Title

- *Content

Constant repairs lead to lost time, higher costs, and delivery delays.

Constant repairs lead to lost time, higher costs, and delivery delays.  Old interfaces don’t meet today’s requirements for precision or responsiveness.

Old interfaces don’t meet today’s requirements for precision or responsiveness.  Machines are isolated, blocking real-time visibility and smart control upgrades.

Machines are isolated, blocking real-time visibility and smart control upgrades.  Human error and long learning curves reduce agility and consistency.

Human error and long learning curves reduce agility and consistency.  Old hydraulic systems waste energy and raise long-term operating costs.

Old hydraulic systems waste energy and raise long-term operating costs.