Single Phase Mini CNC Press Brake for Home-Use

Sheet Metal Equipment Manufacturing Capabilities

MeteWorkMaster

Provide One-Stop Metal Processing Solutions

2000+

Factory Area

150+

Factory Workers

5

R&D Department

150+

Quality Inspection Items

Sheet Metal Equipment Manufacturing Process

Blank Cutting

Remove the oxide layer

Tempering

Primer paint

Punch

Welding

Precision machining

Spray painting

Assembly

Debug

Whole machine verification

Pack and ship

Visiting a Sheet Metal Equipment Manufacturing Factory

Top Equipment and Process Support

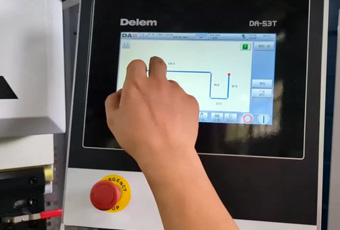

High-precision bending

We have introduced the world's most advanced CNC bending technology to ensure that each bend can achieve an accuracy of ±0.1mm, adapting to the requirements of a variety of complex materials and shapes.

Efficient laser cutting

The laser cutting equipment uses fiber laser technology to provide excellent cutting speed and accuracy, especially suitable for fast cutting of high-strength metal materials, greatly reducing material waste.

Customized production of shearing machines:

For shearing needs, Metalwork Master provides a variety of blade materials and design solutions, which can easily cope with the shearing needs of various materials such as thick plates and thin plates.

Customized Solutions

CustomizationFull-process support to meet personalized needs.

Metalwork Master knows that each customer's needs are unique, so we provide fully customized metal processing services, from initial design to production commissioning, tailoring equipment solutions for different customers' production processes. Whether it is mass production or small batches of high-precision needs, we can provide flexible solutions.

Bending machine customization

A variety of standard models of bending machines are available to meet different metal processing needs

Laser cutting machine and shearing machine

We also provide customers with customized services for laser cutting machines and shearing machines to ensure that they can meet various complex metal processing tasks.

Equipment customization and upgrade

According to customer needs, flexibly adjust equipment configuration and functions, support technical upgrades and modifications of existing equipment, and help customers improve production line efficiency and capacity.

Spare Parts Supply and Equipment Maintenance

Full Life Cycle Equipment Support

We know that the long-term reliability of equipment is critical to our customers. Therefore, Metalwork Master provides a comprehensive spare parts inventory and repair services to ensure that customers' equipment always maintains the highest performance throughout its life cycle.

Spare Parts Guarantee:

We have a powerful spare parts storage system and always have a variety of key components to avoid production stoppages or delays due to parts shortages.

Equipment Maintenance and Upgrade:

We provide technical upgrade services for equipment to help customers achieve efficiency improvement and energy consumption optimization of production lines by updating the core components and software of the equipment.

R&D and Innovation

Forward-looking Technology R&D

Metalwork Master's R&D team is constantly committed to exploring new technologies, especially in smart manufacturing and green processes, to ensure that customers can use the most cutting-edge equipment for efficient production. Our R&D achievements include the latest automated control systems, intelligent monitoring equipment, and energy-saving and emission reduction technologies to help customers reduce energy consumption and operating costs.

Intelligent Equipment R&D:

We are developing intelligent equipment that can achieve remote monitoring and automatic adjustment. Customers can always understand the operating status of the equipment and optimize the settings according to actual production conditions.

Customized Technology R&D:

For the unique needs of different industries, we provide customized R&D services from concept design to prototype testing to ensure that the equipment can seamlessly adapt to the customer's production environment.

Quality Control and Efficient Production Process

Lean Production and Strict Quality Inspection

Metalwork Master uses a strict quality management system (including ISO standard certification) to ensure that each device undergoes the most rigorous testing before leaving the factory. We adopt a full-process quality control method, and every process from raw materials to finished products is subject to high-standard quality inspection to ensure the durability and precision of the equipment.

Comprehensive quality inspection system:

All equipment must pass multiple performance tests during the production process to ensure that the stability, precision and durability of the final product meet or even exceed industry standards.

Efficient production process:

Our intelligent production management system can monitor the production status in real time, effectively reduce the error rate, increase production speed, and ensure on-time delivery.

Customer Success Stories

Automotive industry:

By providing customers with customized bending machine solutions, the efficiency of the production line has been increased by 20%, and the material utilization rate has been significantly improved.

Aerospace:

Provide high-precision metal processing equipment for the aerospace field to help customers maintain high output and low error rates under extremely demanding quality standards.

Construction industry:

Provide shears and laser cutting equipment to large construction companies to support them in producing complex metal structural parts to meet high-strength and high-precision construction requirements.

Global Distribution

Metalwork Master has an extensive global network of distributors and service providers, providing fast-response after-sales support to customers around the world. We work with distributors to provide comprehensive technical training, marketing support, and lifetime technical services.

Contact MetalWorkMaster

Need Assistance?

Download Product Operation Manuals

Installation and Commissioning Guidance

Equipment Maintenance Training

Sample Support for Equipment Spare Parts

Support for Third-party Factory Inspections

Free Technical Consultation Services

Consult Sheet Metal Equipment Experts

- Quick Quotation

- Phone

Join Our Distributors

- Phone

- *Title

- *Content