Single Phase Mini CNC Press Brake for Home-Use

Lifetime Services

- Training

- Accessories support

- Mold customization

- Equipment upgrade

- After-sales service

Lifetime Services

Professional Training Ensures Normal Operation of Equipment

- Training 1

Equipment Operation Training

Press brake operators need to receive comprehensive safety training before operating to ensure the safety of operation and the integrity of the equipment. The following are the safety training contents that operators need to master:

- Training 2

Regular Maintenance

The regular maintenance training content for bending machine operators usually includes the following aspects:

- Training 3

Installation and Debugging Guidance

The installation and commissioning of metal processing equipment is a professional and complex process that requires certain steps and precautions to be followed. The following is a guide to the installation and commissioning of bending machines:

Lifetime Services

Accessory Support

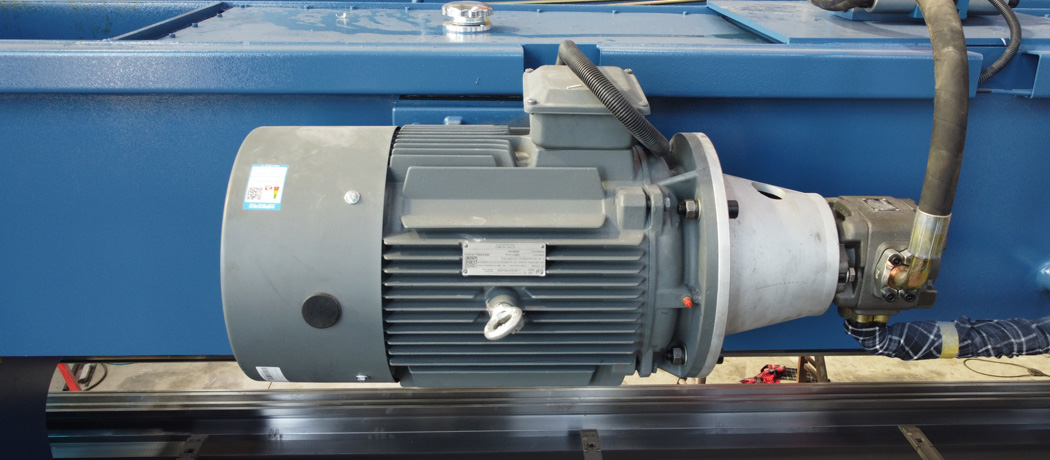

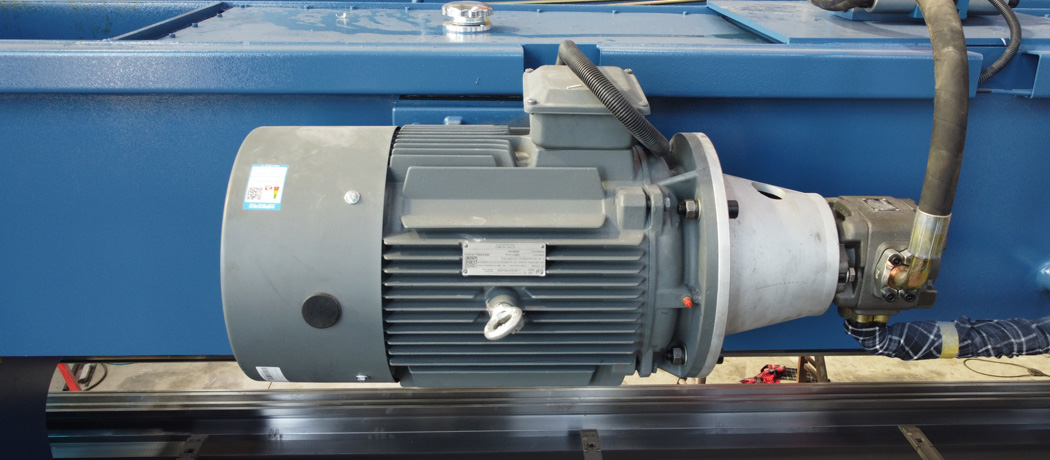

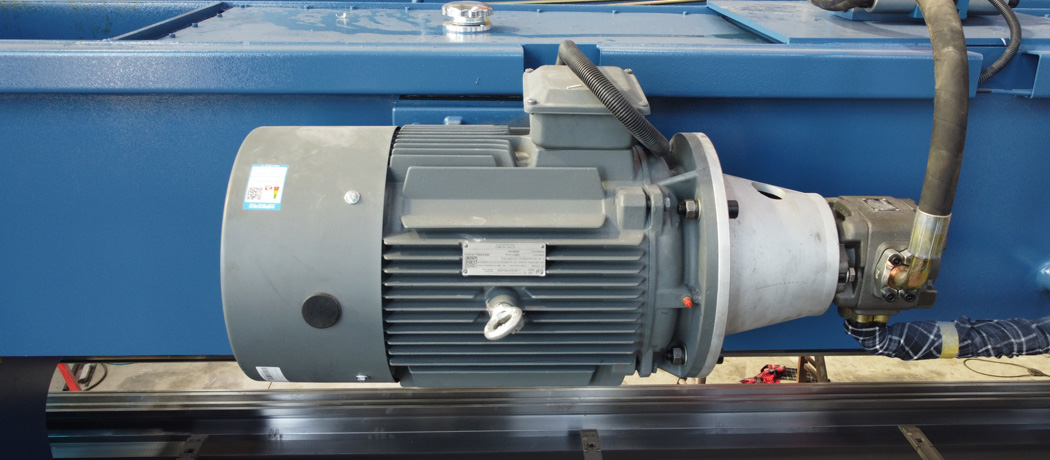

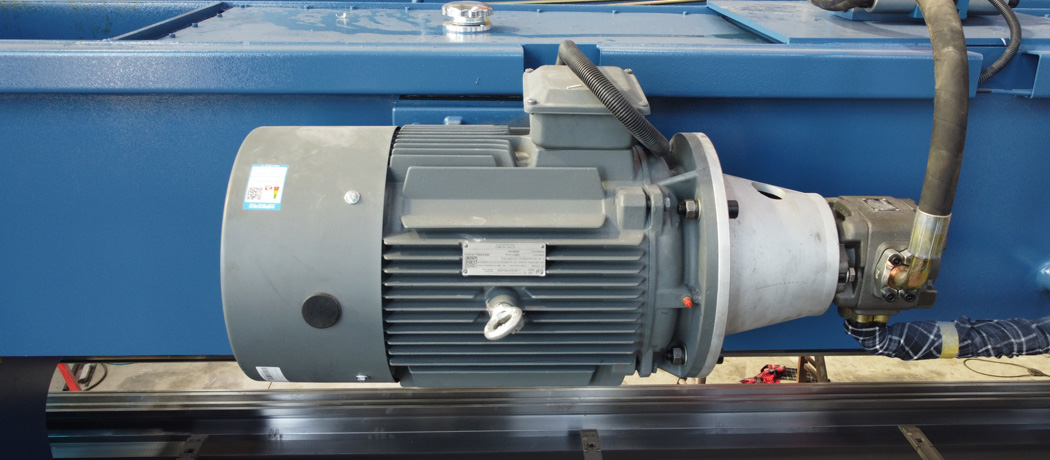

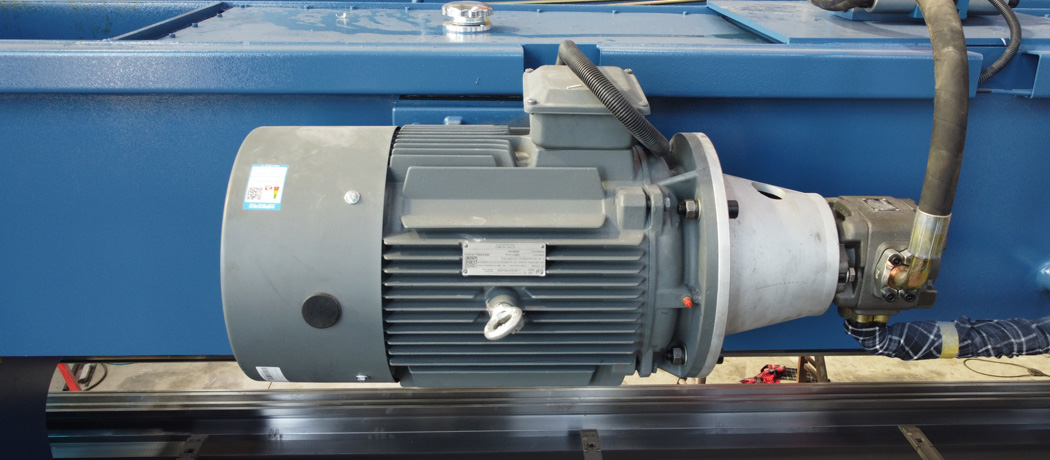

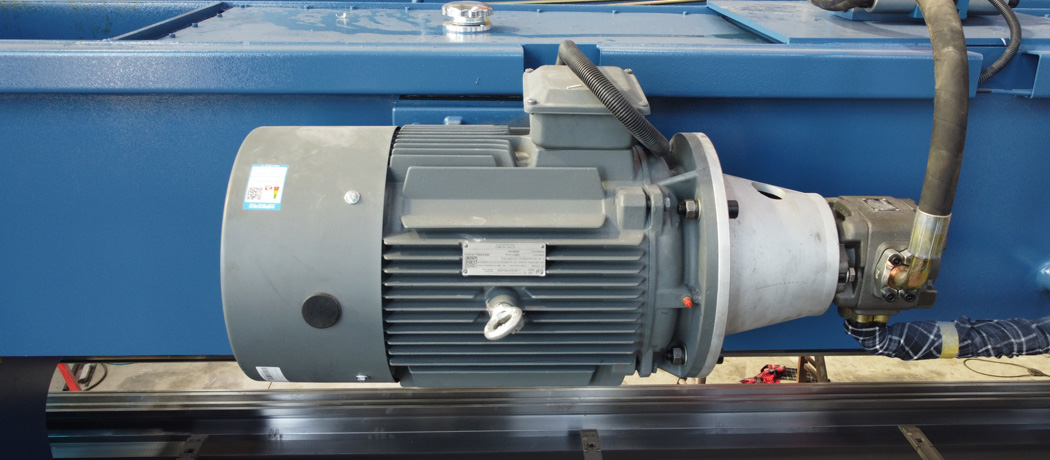

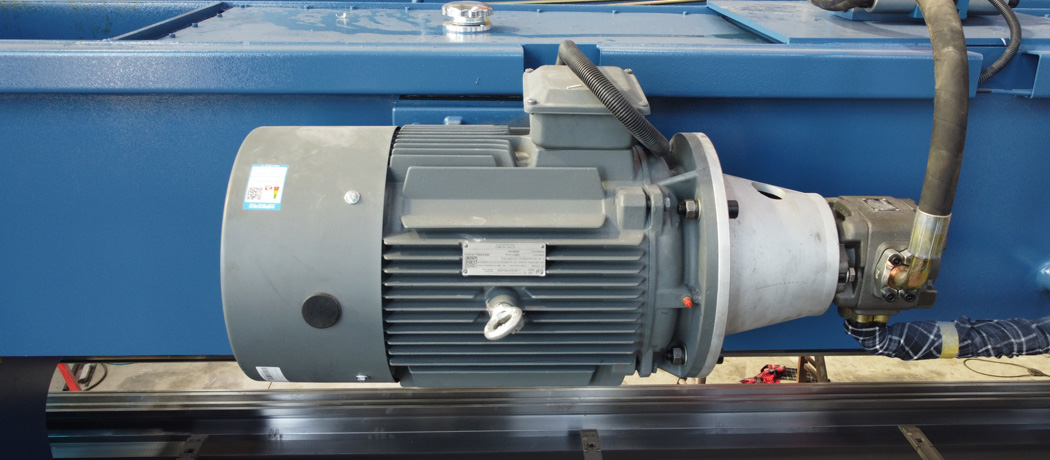

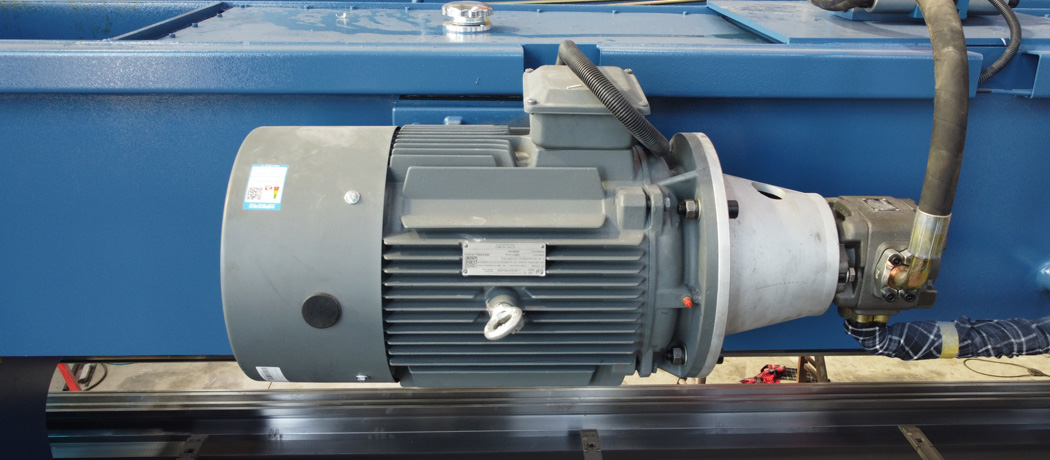

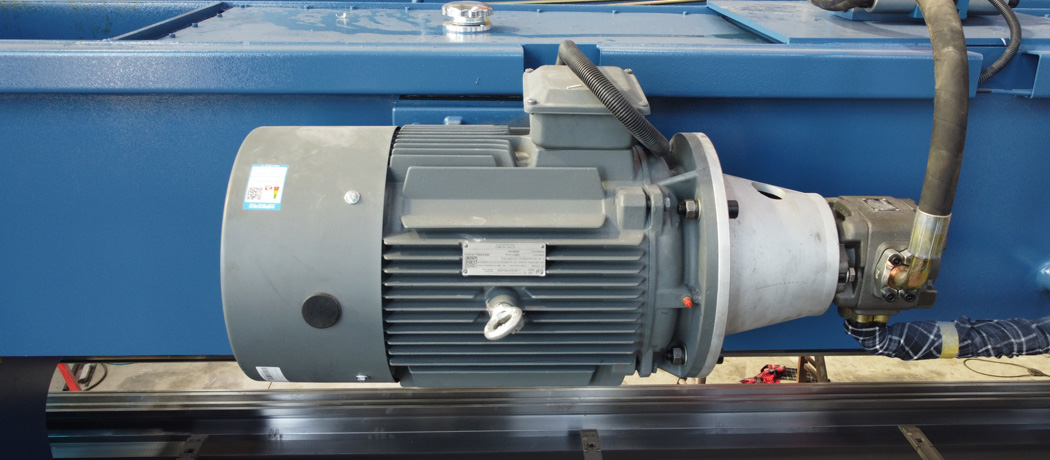

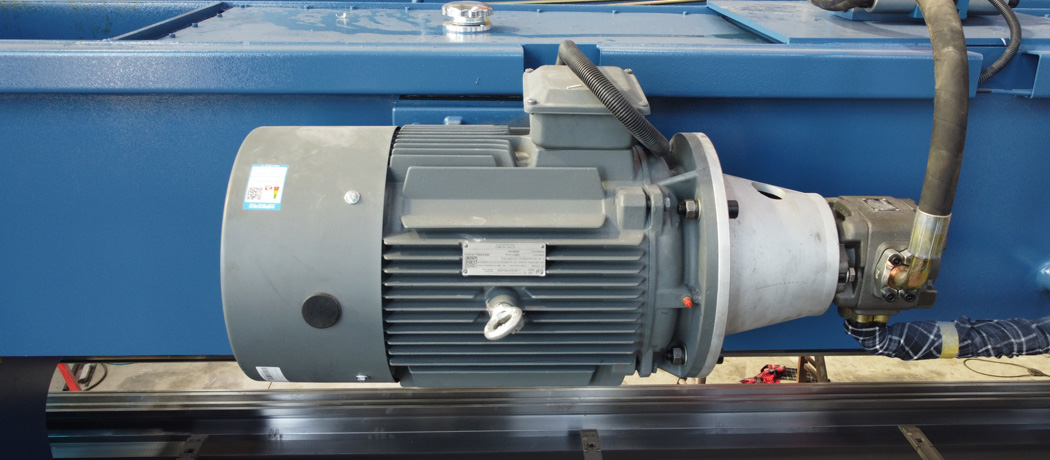

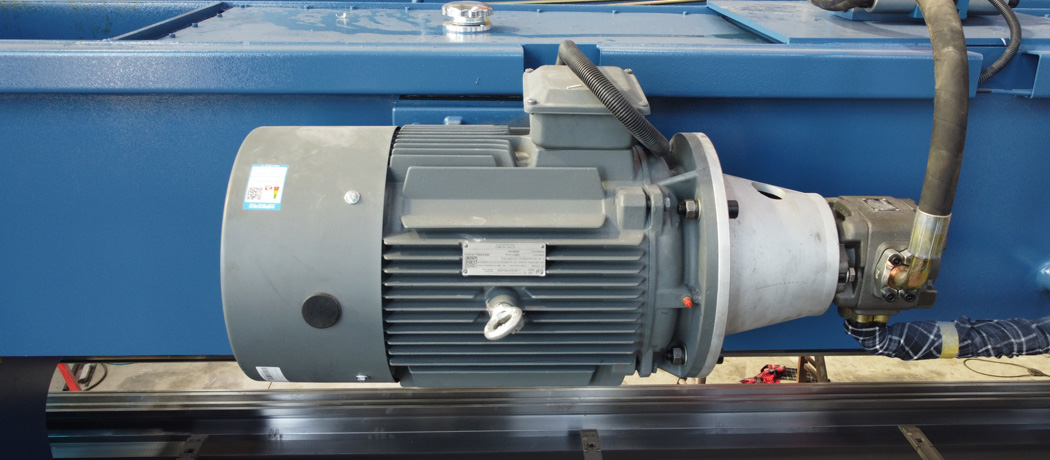

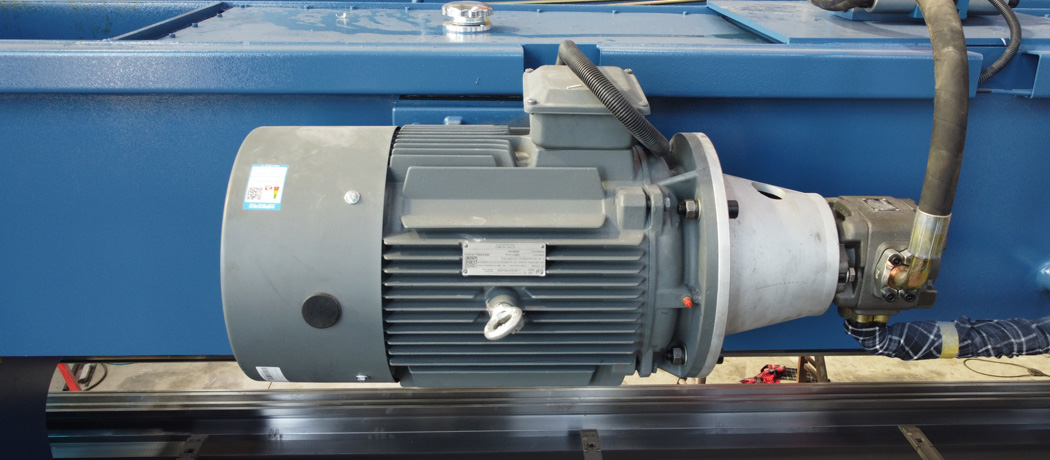

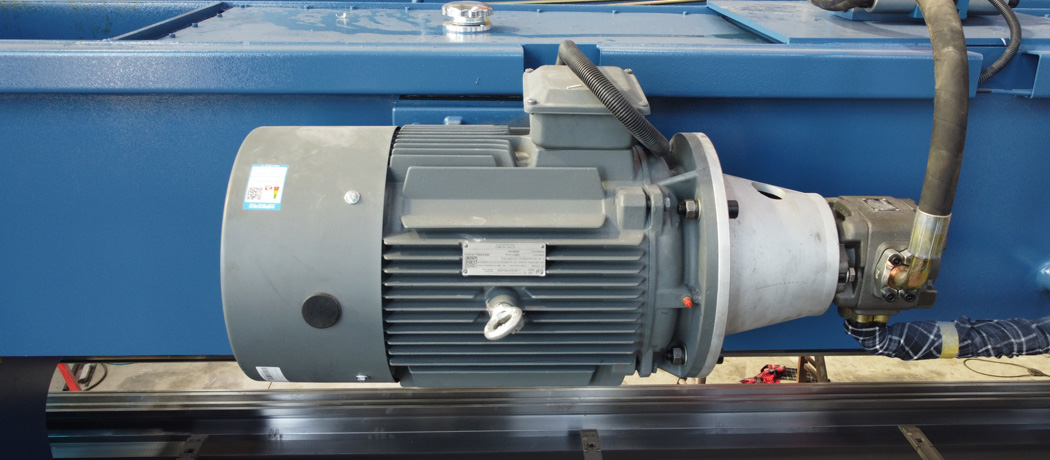

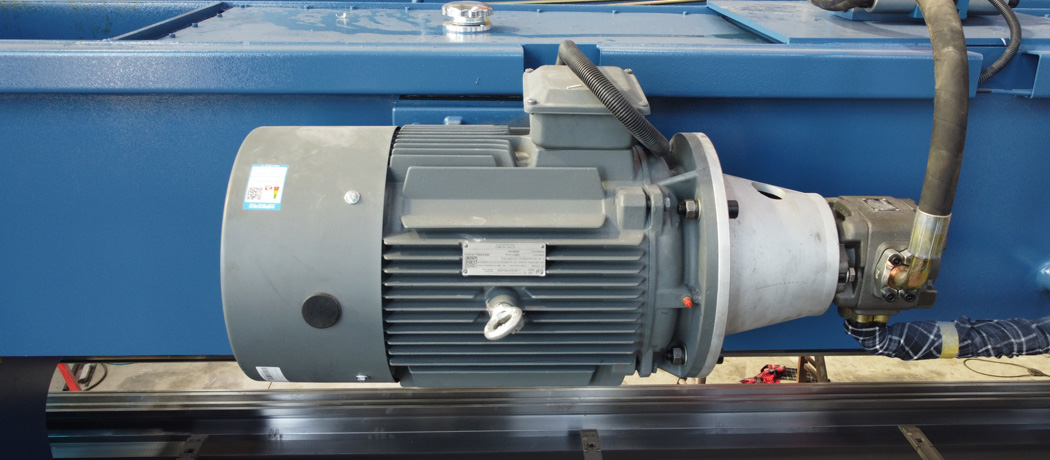

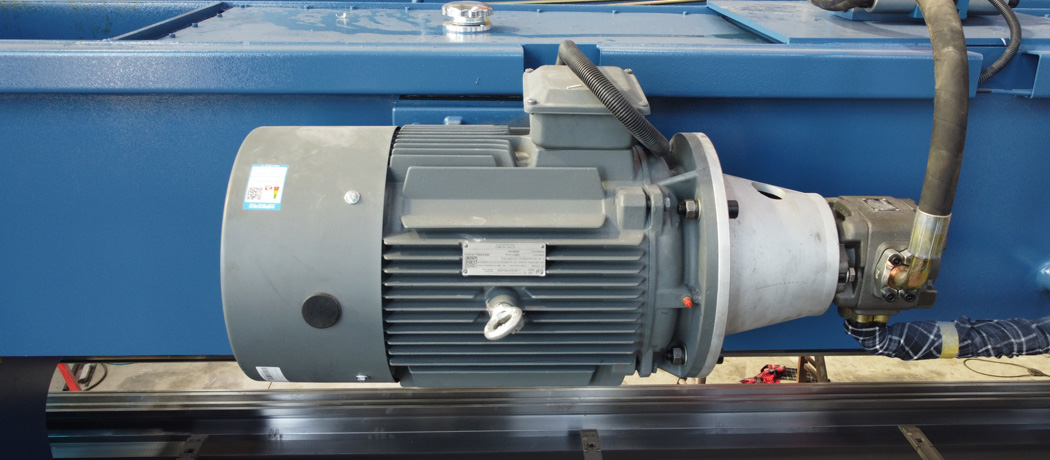

Motor and servo control system

The motor provides power to drive the bending operation, while the servo control system ensures precise control and adjustment of the bending action.

Common motor types include servo motors and stepper motors, while the servo control system includes components such as servo drives and servo controllers.

Learn More

Guide rails and sliders

The guide rails support and guide the movement of the upper and lower dies, ensuring accurate and stable bending.

The slides are mounted on the guide rails, connecting the motor and the upper and lower dies to achieve movement. They typically feature high-precision rolling mechanisms.

Learn More

Upper die seat and lower die seat

The upper die holder secures the upper die, while the lower die holder secures the lower die.

They are typically adjustable to suit the workpiece size and requirements.

Learn More

Transmission device

Converts the motor's rotational motion into linear motion for the upper and lower dies.

Common transmissions include gear drives and belt drives.

Learn More

Control panel

Used to set bending parameters, adjust the bending angle, and monitor the bending process.

This typically includes an LCD display, buttons, or a touch screen.

Learn More

Safety devices

Including light barriers, safety doors, emergency stop buttons, etc., to ensure the safety of operators and equipment.

Learn More

Other accessories

Such as guide wheels, rollers, sensors, etc., used to assist bending operations and monitoring.

Learn More

Hydraulic system

It is composed of hydraulic cylinders, pumps, valves and hydraulic oil storage tanks to provide the force required for bending.

Learn More

Motor and servo control system

This helps accurately position the metal sheet during bending. It typically consists of fingers or stops that can be adjusted to achieve precise bend angles and lengths.

Common motor types include servo motors and stepper motors, while the servo control system includes components such as servo drives and servo controllers.

Learn More

Die

A punch and die set used to bend metal. High-quality dies are essential for achieving precise and consistent bends.

Learn More

Electrical inspection

Regularly check whether the wires, plugs and electrical equipment are working properly to ensure the safety and stability of the equipment.

Learn More

Daily maintenance

This includes cleaning, lubrication, inspection, and checking of key components and controllers to ensure they are functioning properly.

Learn More

Frame

Provide structural integrity and stability to the machine and should be strong and durable to withstand the forces applied during processing.

Learn More

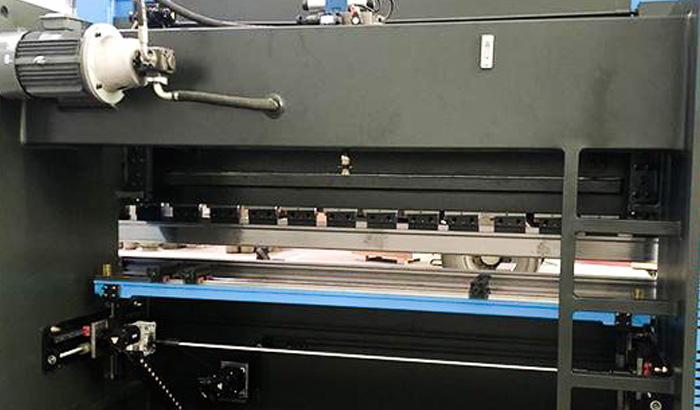

Active beam and base

The beam is the movable part of the machine that applies pressure to the sheet metal, while the base is the fixed part that supports the material being bent.

They should be precisely aligned to ensure accurate and consistent bends.

Learn More

Control system

Allows the operator to set and adjust bending parameters such as bend angle, bend length, and backgauge position.

Advanced control systems such as CNC (Computer Numerical Control) provide high-level precision and automation capabilities.

Learn More

Lifetime Services

Mold Customization

Features of mold customization:

Technical requirements:

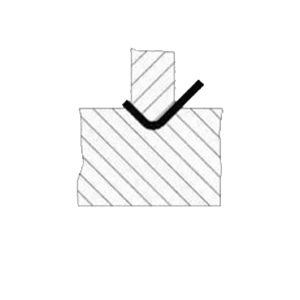

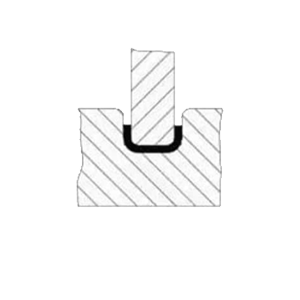

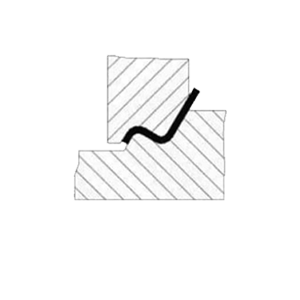

Mold type:

V-shaped molds

U-shaped molds

Z-shaped molds

Lifetime Services

Equipment Upgrades and Renovations

Hydraulic system optimization:

By increasing the diameter of the hydraulic cylinder, using higher pressure hydraulic oil, and improving the response speed of the hydraulic system, the production efficiency of the bending machine can be improved.

Improving accuracy:

Using high-precision displacement sensors and control algorithms to improve the accuracy of the bending machine, reduce errors, and improve product quality.

Energy saving and environmental protection:

Adopt energy-saving design and technology, such as using high-efficiency motors and transmission systems, and using energy-saving hydraulic oil, to reduce energy consumption and environmental pollution.

Control system upgrade:

Introducing advanced CNC systems to improve the automation and intelligence level of equipment, making equipment operation easier, and improving production efficiency and product quality.

Mechanical structure reinforcement:

Reinforce or replace key mechanical structures such as the upper beam and lower beam of the bending machine to improve the stability and load-bearing capacity of the equipment.

Clamping system upgrade:

Upgrading the clamping system, such as using WILA hydraulic clamps, can reduce clamping time, improve clamping accuracy and consistency, and reduce dependence on operator skills.

Mold and tool update

Use higher precision and more durable molds to improve bending accuracy and reduce replacement frequency. For example, the key dimension accuracy of the molds provided by WILA can reach ±0.01mm.

Electro-hydraulic servo system:

Introduce electro-hydraulic servo control system to achieve higher bending accuracy and stability, suitable for fields with high precision requirements.

Intelligent service:

Provide intelligent operation interface and data analysis system to achieve remote fault diagnosis and workflow optimization.

Customized transformation:

Provide customized transformation solutions according to the specific needs of different customers to ensure that the equipment can give full play to its maximum efficiency.

Lifetime Services

After-Sales Service

Mob/WhatsApp:

0086-15156147667

Mob/WhatsApp:

0086-15212339345

Mob/WhatsApp:

0086-15156147667

Mob/WhatsApp:

0086-15212339345

Contact MetalWorkMaster

Need Assistance?

Download Product Operation Manuals

Installation and Commissioning Guidance

Equipment Maintenance Training

Sample Support for Equipment Spare Parts

Support for Third-party Factory Inspections

Free Technical Consultation Services

- Quick Quotation

- Phone

Join Our Distributors

- Phone

- *Title

- *Content