Single Phase Mini CNC Press Brake for Home-Use

plate rolling machine Customization

Customizable

Customization Options for the plate rolling machine

- Customizable 1

Style Customization

We currently have 3 different models of Shearing Machine for you to choose from.

- Customizable 2

Size Customization

We provide customized plate rolling machine sizes to adapt to the plate processing of different products. The following are our regular plate rolling machine sizes.

| Model | Max.rolling thickness (mm) | Max.pre-rollingthickness (mm) | Plate width (mm) |

|---|---|---|---|

| W12NC-25x2000 | 25 | 20 | 2000 |

| W12NC-25x2000 | 25 | 20 | 2500 |

| W12NC-30x2000 | 30 | 25 | 2500 |

| W12NC-30x2000 | 30 | 25 | 2500 |

| W12NC-30x2000 | 30 | 25 | 3000 |

| W12NC-40x2000 | 40 | 32 | 3000 |

| W12NC-50x2000 | 50 | 40 | 3000 |

| W12NC-60x2000 | 60 | 50 | 3000 |

Pleasecontact usfor more customized sizes.

- Customizable 3

Customized Configuration

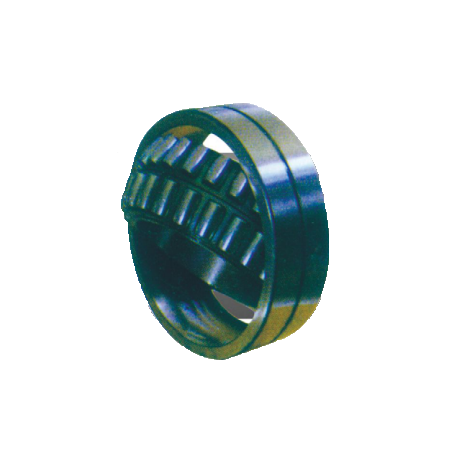

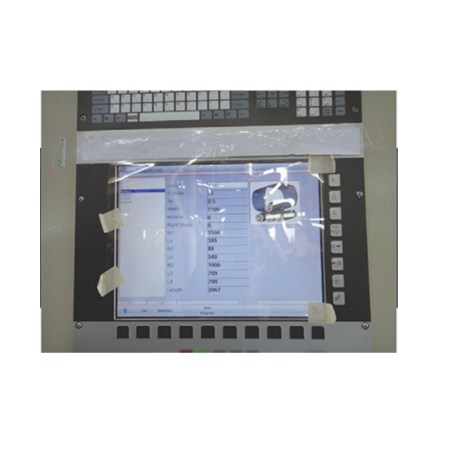

We offer customizable:Cylinder Overhead Type,Roller Bearings,CnC Display Monitor,Hydraulic Motor

Cylinder Overhead Type

Roller Bearings

CNC Display Monitor

Hydraulic Motor

- Customizable 4

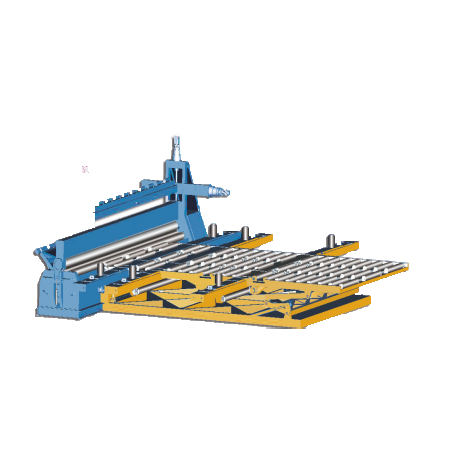

Feeding table Configuration

The feeding table of the plate rolling machine has a continuous feeding function to improve work efficiency, can accurately control feeding to improve overall production efficiency, and can also stabilize plate transportation and work with the plate rolling machine to improve processing accuracy. At the same time, it enhances operational safety by feeding away from dangerous areas and emergency braking functions, and can adapt to different plate specifications and cooperate with different rolling processes to expand the scope of application.

- Customizable 5

Cone Rolling Device Configuration

The cone rolling device of the plate rolling machine can accurately control the cone angle, improve processing accuracy, and flexibly adjust process parameters to adapt to the processing of cones of different specifications, effectively reducing labor intensity and production costs, and is easy to operate, stable and reliable, and can significantly improve Advantages such as cone production efficiency and product quality.

Customized Plate Rolling Machine Solution Cooperation Process

Step 1

Demand Analysis

In industrial manufacturing, automobile, building decoration and maintenance & remanufacturing industries, diverse demands for plate rolling machines in aspects like accuracy and portability due to production features, promoting tech innovation. These machines need to be large-scale high-precision, adaptable to new plates, multifunctional & miniaturized or small & portable.

Step 2

Solution Design and Quotation

This is a solution design and quotation for the plate rolling machine, covering equipment selection, process flow, supporting facilities, and providing detailed cost information for the main machine, supporting equipment and tools, transportation, installation, commissioning, after-sales service, etc. It also includes a project implementation plan and after-sales service commitment.

Step 3

Custom Product Sampling

Plate rolling machine custom product sampling is the process of producing samples according to specific requirements and testing and evaluating them to ensure that the products meet customization standards and customer expectations.

Step 4

Contract and Payment

The plate rolling machine contract and payment covers the legally binding contract content signed by the buyer and seller for the plate rolling machine transaction, including equipment specifications, prices, delivery deadlines, quality assurance and other terms, as well as the corresponding process and conditions for the buyer to pay the seller in the agreed manner and time, so as to ensure the smooth completion of the transaction and the protection of the rights and interests of both parties.

Step 5

Customized Production

Plate rolling machine customized production refers to the process of specially designing and customizing the plate rolling machine in terms of size, performance, function, etc. according to the customer's unique needs and specifications, including preliminary communication, design, production and quality control, so as to meet the customer's specific production application needs.

Step 6

Production Progress Feedback

During the production process of the plate rolling machine, report the progress of the production tasks to relevant parties (such as customers, management, etc.), including the completed processes, current production status, expected completion time, and possible problems or

Step 7

Testing and Product Sampling

Plate rolling machine Testing and Product Sampling is the process of evaluating the plate rolling machine's performance and the quality of its processed products. It involves checking parameters with professional instruments, sampling products, and inspecting them for accuracy, appearance, and properties to ensure compliance with standards, providing a basis for production improvement and quality control.

Step 8

Inspection Report and Videos

Plate rolling machine Inspection Report and Videos comprise a detailed report on the machine's inspection, including performance data and safety checks, along with videos showing its operation and inspection processes. They offer comprehensive information for quality assessment, fault diagnosis, training, and acceptance to ensure the machine's proper use and performance optimization.

Step 9

Packaging, Logistics, and Delivery Report

Plate rolling machine Packaging, Logistics, and Delivery Report details the process from machine packaging and protection, through logistics choices and transit, to final delivery. It includes materials, carriers, tracking, and timing, ensuring transparency and timeliness for customer satisfaction and business relations.

Step 10

Technical Guidance for Installation and Debugging

Plate rolling machine Technical Guidance for Installation and Debugging encompasses professional instructions and on-site support with details on steps, methods, settings, troubleshooting, and solutions to ensure proper, efficient, and safe installation and debugging, helping technicians achieve optimal operation, minimize faults, and enhance efficiency and effectiveness.

Step 11

Lifetime Service

Plate rolling machine Lifetime Service refers to the comprehensive and continuous support provided throughout the entire lifespan of a plate rolling machine, including but not limited to installation guidance, regular maintenance, prompt troubleshooting and repair, parts replacement, performance optimization, and technical consultations, with the aim of ensuring the machine's reliable operation, maximizing its productivity and longevity, and meeting the evolving needs of users.

Customized Plate Rolling Machine Service Advantages

Professional Customization Capability

Plate Rolling Machine Professional Customization Capability is the ability to design, engineer, and manufacture plate rolling machines according to specific customer requirements, integrating advanced technology, experienced engineering, efficient production processes, and strict quality control to meet diverse industrial needs and provide tailored solutions with added services for enhanced customer value and competitiveness.

High Cost-effectiveness

Plate Rolling Machine High Cost-effectiveness means that the plate rolling machine offers a favorable balance between its purchase price, operational costs, maintenance expenses, productivity, and the quality of the rolled plates it produces, providing users with efficient and reliable performance at a relatively reasonable overall cost, thereby maximizing the return on investment and meeting the economic and production demands of various industries.

Close Collaboration with Customers

Plate Rolling Machine Close collaboration with customers refers to the active and in-depth cooperation between the manufacturer of plate rolling machines and its customers, involving continuous communication, understanding of specific requirements and expectations, joint problem-solving, and shared decision-making in aspects such as machine design, customization, production process, installation, training, and after-sales service, with the aim of ensuring customer satisfaction, enhancing the quality and suitability of the machines, and building long-term and mutually beneficial business relationships.

High Quality Assurance

Plate Rolling Machine High Quality Assurance means implementing strict quality control measures throughout the entire production process of the plate rolling machine, from raw material selection to advanced manufacturing techniques, precise assembly, comprehensive performance testing, and meticulous inspection, ensuring that each machine meets or exceeds industry standards and customer expectations in terms of durability, accuracy, stability, and overall performance, thus providing reliable and top-notch equipment for users.

Technical Innovation and Upgrades

Plate Rolling Machine Technical Innovation and Upgrades refer to the continuous efforts in research, development, and application of new technologies, materials, and designs in the field of plate rolling machines, aiming to enhance their performance, efficiency, precision, automation level, and functionality, while also addressing emerging market demands and industry challenges, through improvements such as advanced control systems, optimized mechanical structures, and innovative manufacturing processes.

Comprehensive After-sales Service

Plate Rolling Machine Comprehensive After-sales Service encompasses a range of support activities provided post-purchase, including timely installation, routine maintenance, rapid response to breakdowns, supply of genuine spare parts, technical training for operators, and continuous customer assistance, all aimed at ensuring the long-term reliable operation, optimal performance, and maximum productivity of the plate rolling machine, as well as enhancing customer satisfaction and loyalty.

Frequently Asked Questions

- What is the coil capacity of the Plate Bending Rolling Machine?The Plate Bending Rolling Machine bends and rolls steel and aluminum plates with precision.

- What are the shipping options for international orders?Multiple shipping methods.

- What kind of technical support do you provide after purchase?We offer comprehensive technical support, including on-site installation, training, and 24/7 remote assistance to ensure smooth and efficient operation of your press brake.

Start Customizing

Customized Plate Rolling Machine Quick Quote

- Press Brake

- Laser Cutting Machine

- Shearing Machine

- Plate Bending Machine

- Quick Quotation

- Phone

- Phone

- Phone

- Phone

- Phone

Download Product Operation Manuals

Installation and Commissioning Guidance

Equipment Maintenance Training

Sample Support for Equipment Spare Parts

Support for Third-party Factory Inspections

Free Technical Consultation Services

Join Our Distributors

- Phone

- *Title

- *Content