Single Phase Mini CNC Press Brake for Home-Use

Solutions for the Metal Shelves manufacturing industry

Solutions

The challenges faced by the Metal Shelves manufacturing industry

Orders fluctuate and the production cycle is long

- Orders in the metal shelving industry fluctuate greatly, especially when demand in the retail and logistics industries changes cyclically, and production cycles are relatively long.

- Existing production processes and equipment configurations may not be flexible enough to handle these fluctuations, leading to lead delays and inventory pressures.

Environmental pressure and energy consumption management

- In the production of metal shelves, equipment ops generate much exhaust gas, waste water & noise, posing great pressure on env protection.

- The cost of electricity and energy consumed in the production process is also an important part of the production cost, and how to effectively control energy consumption and reduce emissions has become a problem that manufacturers must face.

Production capacity and equipment adaptability

- Metal shelf design needs & production batches vary. Making equipment flexible for diff specs, shapes & custom prods is key for mfrs in equip selection.

Fierce competition in the market and homogenization of product

- In metal shelf market, comp is intensifying. Many mfrs' shelf prods are alike with little price diff, leading to severe prod homogenization.

- Manufacturers need to work product quality, design innovation, and brand building to stand out and compete for a larger market share.

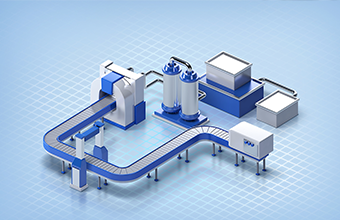

MetalWorkMaster Solutions for manufacture of metal products

Presenting Advanced and Efficient Machine Tooling Systems

Technology advances enable production optimization via integrating automation and intelligent techs. This leads to automated management, heightened efficiency from streamlined workflows and reduced downtime, as well as improved quality in precision and consistency, strengthening market competitiveness.

Enhancing Quality Control and Precision Management

We provide high-precision, consistent machine tools to ensure accuracy and uniformity in metal shelf manufacturing. By integrating advanced inspection technology and a comprehensive quality management system, we rigorously control every step of the production process, guaranteeing reliable and stable product quality.

Precision

Our equipment features high-precision machining for precise shelf dimensions and shapes.

Stability

Equipment operates with high stability, ensuring continuity and consistency in the production process.

Adaptability

Machines adapt to diverse metal bracket specs and materials, offering flexibility.

Automation Level

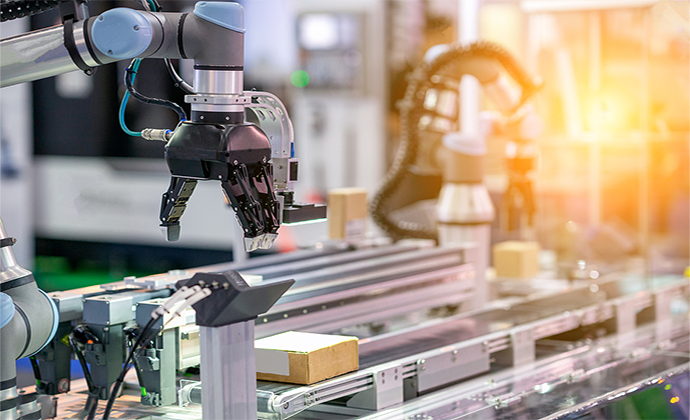

Advanced automation streamlines production, hikes output, and steadies quality by slashing human errors and variability.

Optimizing Cost Control and Energy Management

Our machine tools are designed to be efficient and energy-saving, helping to significantly reduce costs in materials, labor, and energy consumption. By optimizing production processes and designs, we enable economies of scale and cost control, improving overall profitability.

Driving Technological Innovation and Industry Upgrades

Intelligent robots are used to carry out welding, assembly and other tasks for parts, which has improved production efficiency and product quality and promoted the entire industry to upgrade from traditional assembly line production to intelligent production.

Cooperate with the School of Mechanical Engineering of local universities to jointly research and develop new numerical control processing technologies. The universities provide theoretical research support and talent cultivation, and the enterprises provide practical sites and research and development funds, which accelerates the process of technological innovation.

Metal Shelf Production Line Solution

Hinge Production Line for Metal Shelf Manufacturing

Start Customizing

Customization of Sheet Metal Equipment for Metal Shelf Manufacturing

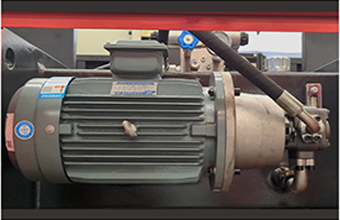

Metal Shelf ProcessingPress Brake

It is used to bend metal sheets according to design requirements to produce the shapes of various parts of metal shelf.

Choose the right type of press brake according to your specific needs: torsion bar series, electro-hydraulic synchronous series, all-electric series, tandem press brake, panel press brake

Press Brake Customization

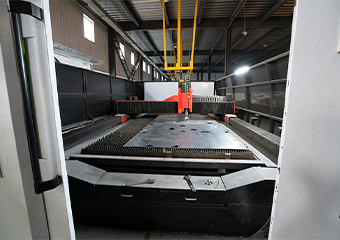

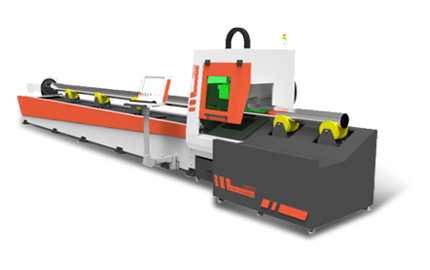

Metal shelf ProcessingLaser Machine

Used to cut metal sheets to make metal shelf frames and other parts.

Laser Machine Customization

Metal shelf Processing

Press Brake

Bend the sheets according to the set angles and dimensions.

Shearing Machine Customization

metal shelf ProcessingPlate Rolling Machine

Used to cut metal sheets to make metal shelf frames and other parts.

Plate Rolling Machine CustomizationSuccessful Cases

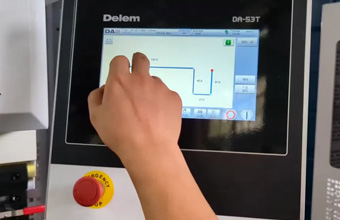

A medium-sized shelf manufacturer

The equipment has a very high precision and can achieve the cutting of complex designs. The operation interface of the machine is simple and the training is quick, so employees can quickly get the hang of it.

A large-scale warehousing company

Since the introduction of this bending machine, our production cycle has been shortened by approximately 30%. Especially in the production of customized shelves in large quantities, it has performed excellently. The reliability and precision of the machine have exceeded our expectations and solved many problems caused by the aging of previous equipment.

A retail shelf supplier

The plate shearing machine equipment we purchased is highly efficient. The machine operates stably and can process a large number of metal plates in a short time. It has greatly improved our production efficiency, reduced manual operations and errors, and is very suitable for our storage rack production.

Contact MetalWorkMaster

Need Assistance?

Download Product Operation Manuals

Installation and Commissioning Guidance

Equipment Maintenance Training

Sample Support for Equipment Spare Parts

Support for Third-party Factory Inspections

Free Technical Consultation Services

Consult Sheet Metal Equipment Experts

- Quick Quotation

- Phone

Join Our Distributors

- Phone

- *Title

- *Content