Single Phase Mini CNC Press Brake for Home-Use

Shearing Machine Customization

Customizable

Customization Options for the Shearing Machine

- Customizable 1

Style Customization

We currently have 2 different models of Shearing Machine for you to choose from.

- Customizable 2

Size Customization

We provide customized Shearing Machine sizes to adapt to the plate processing of different products. The following are our regular Shearing Machine sizes.

| Model | Dimension (L×W×H)(mm) | Model | Dimension (L×W×H)(mm) |

|---|---|---|---|

| 4x2500 | 3130x1500x2070 | 20x2500 | 3370x2015x2575 |

| 6x2500 | 3150x1600x2170 | 20x3200 | 4070x2015x2575 |

| 8x4000 | 4670x1600x2170 | 20x4000 | 4870x2015x2675 |

| 10x2500 | 3190x1600x2170 | 20x5000 | 5870x2115x2875 |

| 12x2500 | 3270x1850x2315 | 20x6000 | 6870x2300x3200 |

| 12x6000 | 6770x2100x2750 | 25x2500 | 3390x2200x2700 |

| 16x2500 | 3270x1850x2315 | 32x2500 | 3490x2440x2915 |

| 16x4000 | 4770x1850x2315 | 40x3200 | 4230x2500x3500 |

Pleasecontact usfor more customized sizes.

- Customizable 3

Customized System

We offer customizable systems:DAC360,E21S,E200-S,P40T

DAC360

E21S

E200-S

P40T

- Customizable 4

Backgauge Configuration

1. Backgauge use ball screw to improve accuracy.

2.Backgauge driven by motor with digital display.

3.Our machine add frequency inverter, X axis can one time positioning, if do not add this part, X axis cannot one time positioning.

- Customizable 5

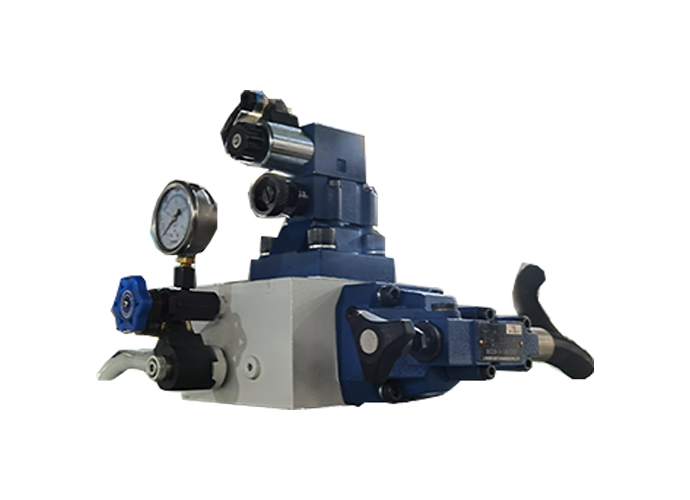

Hydraulic Valve Configuration

Adopt the advanced hydraulic integrated valve block which is in compactstructure and will reduce piping connections, and improves systemreliability and maintainability

Customized Shearing Machine Solution Cooperation Process

Step 1

Demand Analysis

The demand for shearing machines is driven by the manufacturing (automotive, aerospace, metal processing, etc.), construction, and electronic industries, and is influenced by technological advancements (automation, precision), market trends (customization, environmental protection), with developed regions having a large demand for high-end ones and developing regions showing rapid growth potential.

Step 2

Solution Design and Quotation

The design and quotation of shearing machines involve understanding customer needs, selecting the right type, determining specifications, choosing blade materials, considering automation, designing auxiliaries, and calculating various costs (machine, blade, optional items, installation, after-sales) to arrive at the total price, as exemplified by the price ranges of certain domestic and imported models.

Step 3

Custom Product Sampling

Shearing machines custom product sampling entails gathering customer requirements, conducting design and engineering, constructing and testing a prototype, sampling and evaluating performance, obtaining customer feedback for iteration, and finalizing for production to meet the customer's specific material cutting needs.

Step 4

Contract and Payment

For shearing machines, a well-structured contract covering specification details, delivery terms, quality assurance and warranty, installation and training, along with a clear payment plan including schedule, methods, and provisions for penalties and incentives, is crucial to safeguard the interests of both the buyer and the seller and ensure a smooth business transaction.

Step 5

Customized Production

Shearing machines customized production involves tailoring the machine's design, specifications, and features to meet specific customer requirements regarding materials, cutting capabilities, automation levels, etc., through a process that includes detailed consultation, engineering design, precise manufacturing, and strict quality control to deliver a unique and highly functional shearing solution.

Step 6

Production Progress Feedback

Shearing machines Production Progress Feedback pertains to the regular communication and reporting of the status of shearing machine production, including details such as component fabrication, assembly progress, quality inspection results, and any potential delays or issues, to keep stakeholders informed and enable timely decision-making and adjustments to ensure the timely and satisfactory completion of production.

Step 7

Testing and Product Sampling

Shearing machines Testing and Product Sampling refers to the process of evaluating the performance, functionality, and quality of shearing machines through various tests and the collection of sample cuts to ensure they meet the required standards and specifications for safe and efficient operation in different industrial applications.

Step 8

Inspection Report and Videos

Shearing machines Inspection Report and Videos refer to the comprehensive inspection reports and accompanying videos that record the inspection process and results of shearing machines, including their mechanical performance, safety features, and electrical systems, to provide objective evaluations and references for the quality and operation of the machines

Step 9

Packaging, Logistics, and Delivery Report

Once the product passes rigorous quality inspections and packaging and logistics arrangements are completed, we will provide a detailed delivery report, including information on the packaging, shipping route, and estimated arrival time, ensuring that you are informed of the shipping status in a timely manner.

Step 10

Technical Guidance for Installation and Debugging

Shearing Machine Technical Guidance for Installation and Debugging is a set of comprehensive instructions. It details proper installation steps at the site, such as machine positioning, leveling, power and utility connections, calibrating key parts like blade gap and cutting angle, plus startup and debugging guidance to ensure the machine cuts materials precisely, efficiently and safely.

Step 11

Lifetime Service

Shearing Machine Lifetime Service means the all-round and ongoing support during the machine's whole operation life, covering regular maintenance like lubrication, inspection, part replacement, troubleshooting, possible software updates, and operator training to ensure its reliable performance, long life, high productivity, and adaptation to emerging issues and tech changes.

Customized Shearing Machine Service Advantages

Professional Customization Capability

Shearing Machine Professional customization capability is the manufacturer or provider's ability to design and build machines to individual customers' unique needs, requiring industry knowledge, engineering skills to adjust parameters, and using quality materials for optimal performance in various sectors.

High Cost-effectiveness

Shearing Machine High Cost-effectiveness means a favorable balance of initial cost, operating expenses, and output quality and productivity over its lifespan. It has a reasonable price, low ongoing costs, and high value in cutting, giving a good return on investment and being more attractive than less cost-effective alternatives in metalworking and related industries.

Close Collaboration with Customers

Shearing Machine Close collaboration with customers means the active, continuous engagement between manufacturers/suppliers and users. Starting with understanding user needs like materials, precision, volume, and constraints, it extends through design (with feedback for customization), production (with progress updates), and post-sale (installation, training, support). This ensures the machine exceeds expectations, boosting satisfaction, loyalty, and mutual success.

High Quality Assurance

Shearing Machine High Quality Assurance is the set of measures by manufacturers to ensure machines meet/exceed strict standards. It uses quality materials/components, conducts checks from part fabrication to final assembly/testing, corrects defects, and adheres to standards/certifications, giving customers confidence in a reliable, long-lasting cutting equipment.

Technical Innovation and Upgrades

Shearing Machine Technical Innovation and Upgrades mean continuous efforts in improving shearing machines' design, functionality and performance. It includes applying new tech like better control systems, using quality materials, developing innovative blade designs and integrating intelligent features. These upgrades boost productivity, accuracy and help machines adapt to industry changes, offering more advanced cutting solutions.

Comprehensive After-sales Service

Shearing Machine Comprehensive After-sales Service means the all-round support from manufacturers or suppliers after purchase, including installation guidance, operator training, quick response to breakdowns, supplying genuine parts, regular follow-up, and technical consultation, aiming to boost customer satisfaction and build long-term ties.

Frequently Asked Questions

- What are the common faults and solutions for shearing machine maintenance services?The service and support of the shearing machine covers repair services (common faults and solutions, repair procedures, repair cost calculation), maintenance services (daily and regular maintenance content, charging standards), technical support (obtaining information, consulting channels, training service content and methods) and accessories supply (purchase channels, quality warranty status, replacement and installation methods) and other aspects.

- What is the maximum and minimum thickness that the shearing machine can cut?A shearing machine used in various industries for cutting materials has different types like manual, mechanical, hydraulic and pneumatic ones, diverse applications in metal processing, textile and agriculture, and key technical parameters including shearing thickness, length, angle and blade clearance.

- What are the characteristics and applicable scenarios of oblique-edge shears and flat-edge shears?A shearing machine used in various industries for cutting materials has different types like manual, mechanical, hydraulic and pneumatic ones, diverse applications in metal processing, textile and agriculture, and key technical parameters including shearing thickness, length, angle and blade clearance.

- What is the difference between hydraulic shears and mechanical shears?A shearing machine used in various industries for cutting materials has different types like manual, mechanical, hydraulic and pneumatic ones, diverse applications in metal processing, textile and agriculture, and key technical parameters including shearing thickness, length, angle and blade clearance.

Start Customizing

Customized Shearing Machine Quick Quote

- Press Brake

- Laser Cutting Machine

- Shearing Machine

- Plate Bending Machine

- Quick Quotation

- Phone

- Phone

- Phone

- Phone

- Phone

Download Product Operation Manuals

Installation and Commissioning Guidance

Equipment Maintenance Training

Sample Support for Equipment Spare Parts

Support for Third-party Factory Inspections

Free Technical Consultation Services

Join Our Distributors

- Phone

- *Title

- *Content