Single Phase Mini CNC Press Brake for Home-Use

Language:

Home / All / Metalworking Machinery / Metal Forming Machine / Ironworker / Q35Y-30 New Hydraulic Ironworker Machine CNC Punching Equipment | Powerful Hydraulic System

Q35Y-30 New Hydraulic Ironworker Machine CNC Punching Equipment | Powerful Hydraulic System

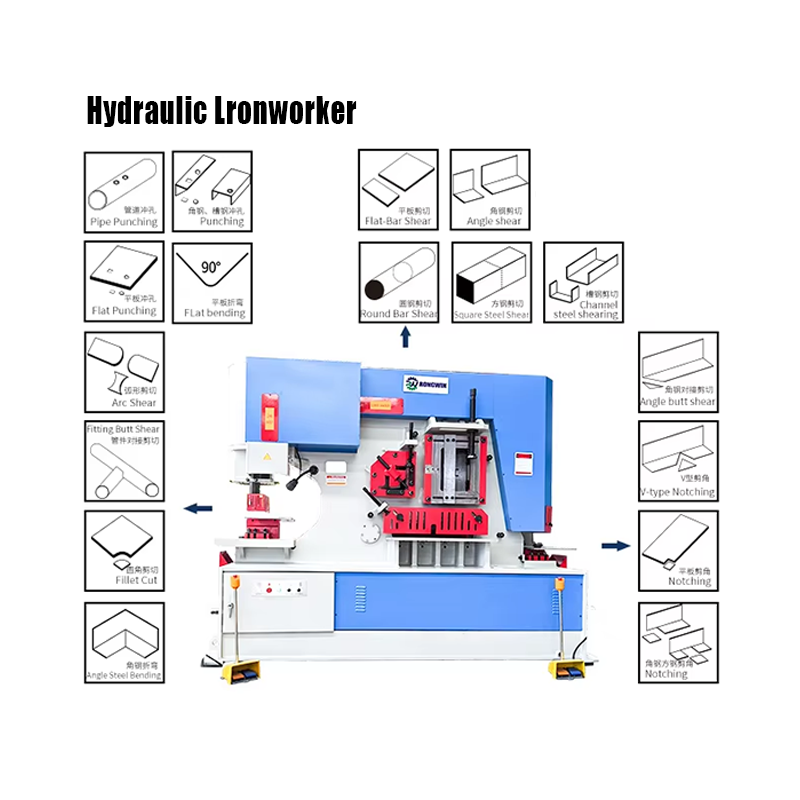

The Hydraulic Ironworker is a versatile, heavy-duty machine for punching, shearing, and bending with CNC and hydraulic power.

| Share | |

|---|---|

| Categories | Ironworker |

| Brand | MetalWorkMaster Smart Custom Metal Solution Expert |

| Model | Q35Y-30 |

| power | Hydraulic |

| Voltage | 220v 380v |

| Warranty period | 1 Year |

| Product name | hydraulic punching machines |

| Model | Q35Y-30 |

| MAX punching diameter | 30mm |

| Color | Customized |

| Dimensions (length × width × height) | 1600X800X1800 |

| Motor power (kW) | 5.5 |

| brand | Rongwin |

| Unit Price | US $ 8000-5000 / piece |

| FOB port | shanghai |

| Terms of Payment | L/C, T/T |

| Update Time | Mar 1,2026 |

Detail Information

Q35Y Series Hydraulic Lronworker

Q35Y Series CNC Hydraulic Ironworker Machine: Advanced Multi-Function Metalworking Solution with Low Maintenance and High Efficiency

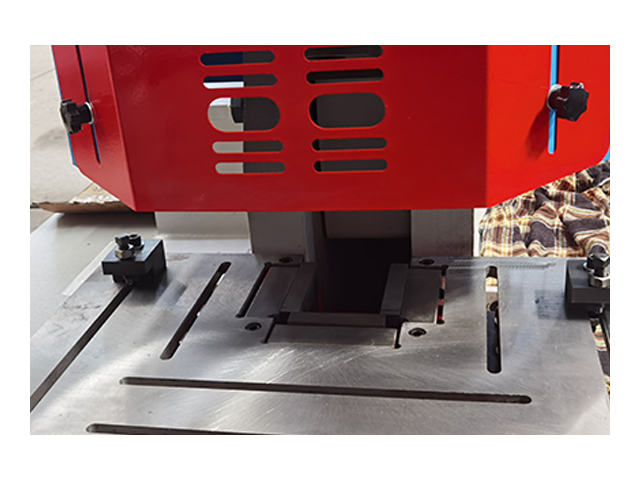

The Q35Y Series CNC Hydraulic Ironworker is designed with advanced technology, offering easy operation, low energy consumption, and minimal maintenance. This versatile machine performs multiple functions, including punching round, square, and rectangular holes; shearing steel plate, flat steel, angle steel, C-groove, and H-shaped steel; bending steel plates and angle steel; and notching and bending various shapes like bars, channels, and pipes. With top-quality components, it is the best choice for metalworking applications.

Q35Y Series Hydraulic Lronworker Application Scenarios

Q35Y Series Hydraulic Lronworker Advantage

Feature 1

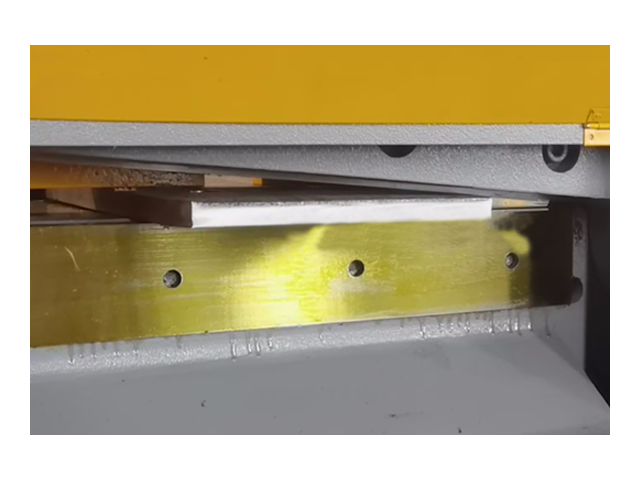

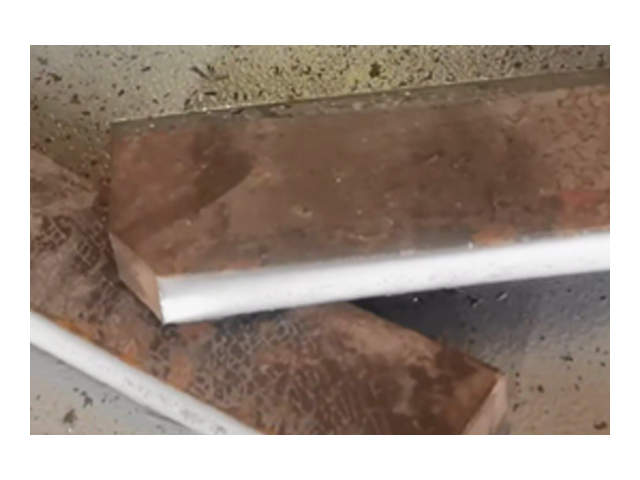

Shearing station

This station can realize thecutting of angle steel,channel steel and sheetmetal.

Feature 2

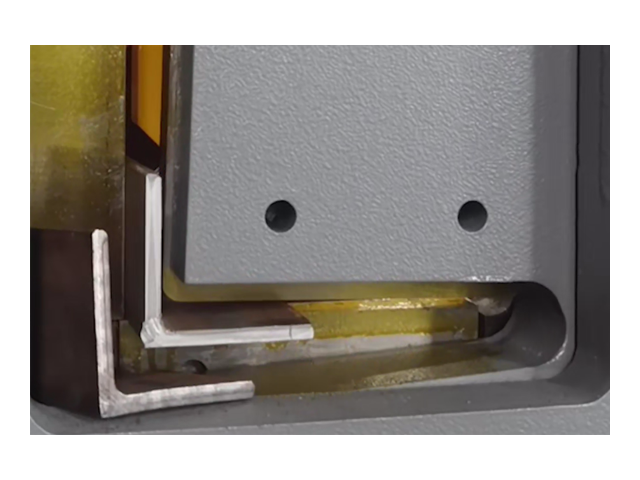

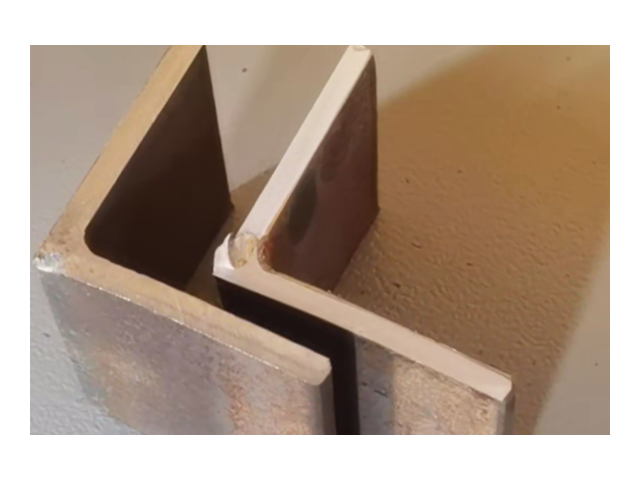

Notching station

This station can be used forvarious types of corner cutting

Feature 3

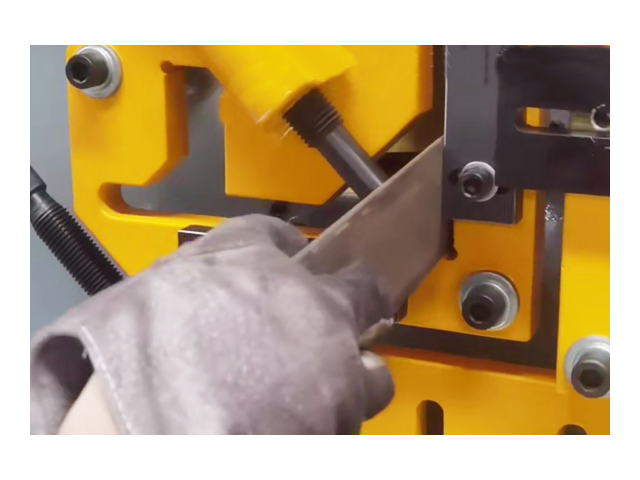

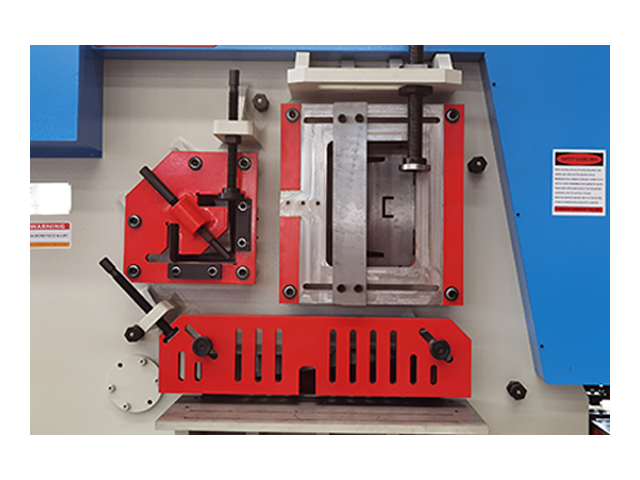

Punching station

This station can be punched.lf othermolds are installed on this station,you can also perform bending, pipedie shearing, shutter blind punchingpunching large holes, channel steel,I-beam, and web punching.

Q35Y Series Hydraulic Lronworker Technical Parameters

Q35Y Series hydraulic Ironworker offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Model

Q35Y -series | Punching pressure (T) | Material strength (mm) | Max. length of cylinder stroke(mm) | Trips frequency (times/min) | Punching thickness(mm) | Max. punching diameter (mm) | Depth of throat (mm) | Motor power (kw) | Overall dimensions (LxWxH mm) |

16Y-60T | 60 | ≤450 | 80 | 10-20 | 16 | 25 | 300 | 5.5 | 1400x700x170 |

20Y-90T | 90 | ≤450 | 80 | 12-22 | 20 | 30 | 335 | 7.5 | 1600x800x1800 |

25Y-120T | 120 | ≤450 | 90 | 8-18 | 25 | 38 | 480 | 11 | 1800x960x2000 |

|

30Y-160T

|

160

|

≤450

|

100 | 6-16 |

30

|

40 | 600 | 15 | 2000x1050x2450 |

|

40Y-200T

|

200

|

≤450

|

110 | 6-16 |

40

|

45 | 535 | 18.5 | 2200x1050x2450 |

|

50Y-250T

|

250

|

≤450

|

200 | 6-16 |

50

|

45 | 600 | 18.5 | 2600x1440x2500 |

Parameters within this range reflect the wide applicability of the Q35Y Series Hydraulic Ironworker in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

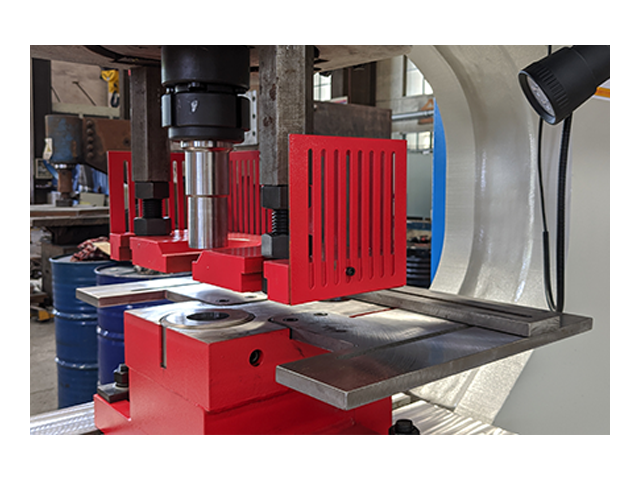

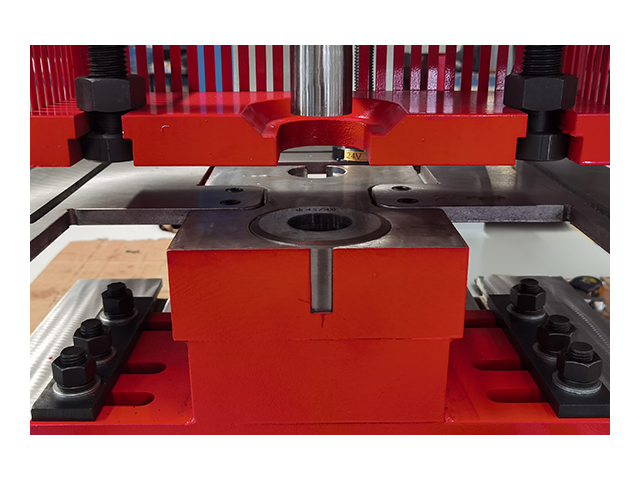

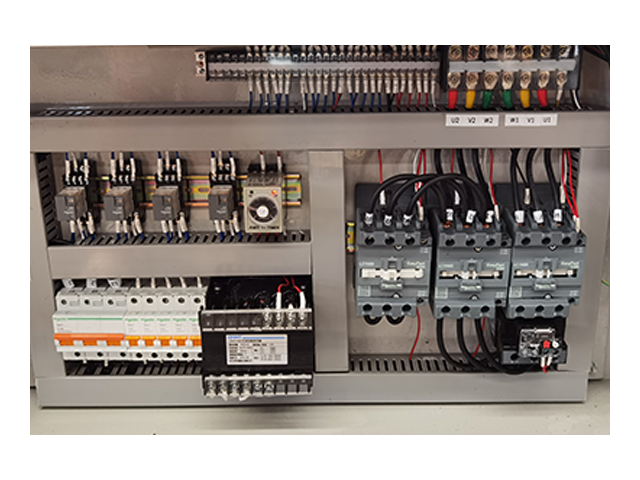

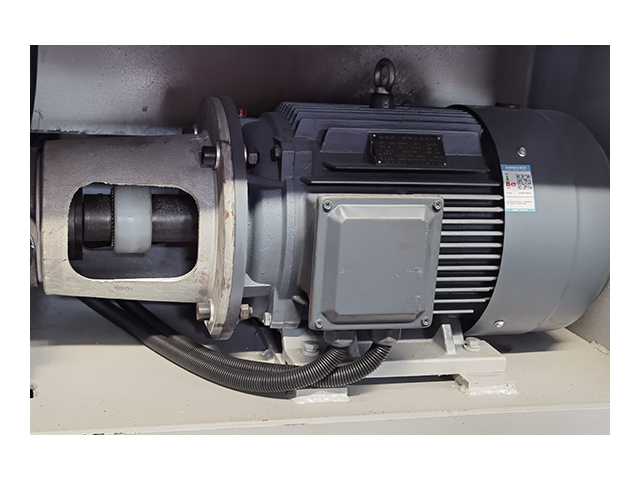

Q35Y Series Hydraulic Ironworker Details Display

Punching parts

Electric cabinet

Main motor

Upper and

lower dies

Q35Y Series Hydraulic Lronworker FAQ

What are the main advantages of the Q35Y Series Hydraulic Ironworker electro-hydraulic synchronization system?

Electro-hydraulic

What types of materials can the Q35Y Series Hydraulic Ironworker process?

Q35Y series hydraulic Ironworker is suitable for bending various metal plates such as stainless steel, carbon steel, aluminum, etc.

What are the main features of the Q35Y Series Hydraulic Ironworker ?

Key features include:

This station can realize thecutting of angle steel,channel steel and sheetmetal.

This station can be used forvarious types of corner cutting

This station can be punched.lf othermolds are installed on this station,you can also perform bending, pipedie shearing, shutter blind punchingpunching large holes, channel steel,I-beam, and web punching.

Can the Q35Y Series Hydraulic Ironworker be customized to meet specific needs?

Yes, the Q35Y series hydraulic Ironworker can be customized with various options, such as automatic backgauge, crowning system

Review

- Loading...

Join Our Distributors

Are you looking for a partnership with huge market potential and generous profit margins? Asour distributor, you will receive comprehensive market support, high-quality product resourcesand professional business training. Contact us now to learn more about becoming ourdistributor and start your journey to success!

- Phone

- *Title

- *Content

Join Our Distributors

Are you looking for a partnership with huge market potential and generous profit margins? Asour distributor, you will receive comprehensive market support, high-quality product resourcesand professional business training. Contact us now to learn more about becoming ourdistributor and start your journey to success!

- Phone

- *Title

- *Content