Fiber Laser Cutter vs. CO₂ Laser Cutter

Fiber Laser Cutter vs. CO₂ Laser Cutter: Which is Right for Your Business?

Understanding the Basics of Fiber and CO₂ Laser Cutters

What is a Fiber Laser Cutter?

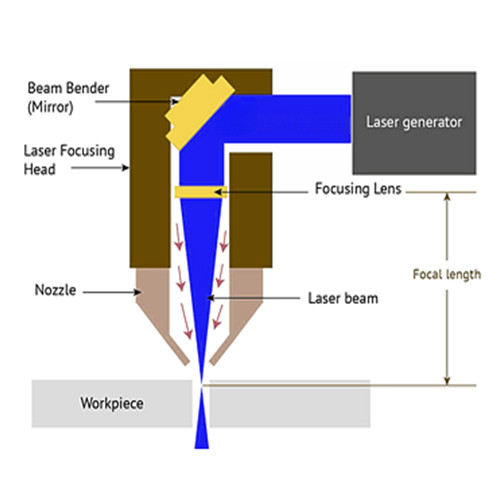

A fiber laser cutter uses a solid-state laser. This laser is made by a fiber optic cable that has rare-earth elements, like ytterbium. This high-speed fiber laser cutting machine is great for cutting metals.

What is a CO₂ Laser Cutter?

Key Differences Between Fiber and CO₂ Laser Cutters

Cutting Speed and Precision

Operational Costs and Efficiency

Material Compatibility

| Features | CO₂ laser cutting machine | |

| Applicable materials | Mainly used for non-metal, can cut thin metal | Mainly used for metal cutting |

| Wavelength | 10.6μm (suitable for non-metal) | 1.06μm (suitable for metal) |

| Cutting quality | Smooth cut, suitable for fine engraving | Higher metal cutting efficiency |

Equipment cost | Relatively low | Higher price, low maintenance cost |

Energy consumption | Relatively high | More energy-efficient |

Application areas | Widely used in advertising, clothing, packaging, woodworking, etc. | Mainly used in metal processing, automobile, aviation and other industries |