Fiber Laser Cutter vs. CO₂ Laser Cutter: Which is Right for Your Business?

Introduction

Understanding the Basics of Fiber and CO₂ Laser Cutters

What is a Fiber Laser Cutter?

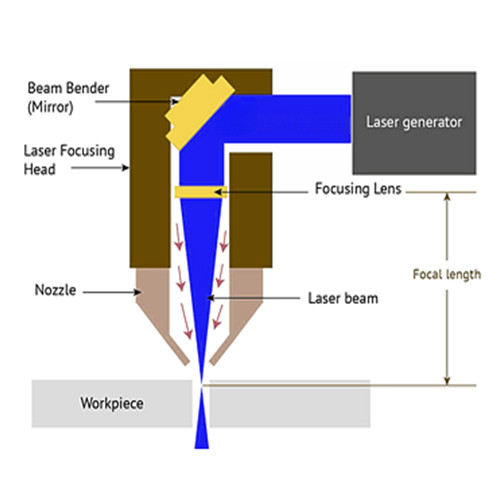

A fiber laser cutter uses a solid-state laser generated by a fiber optic cable doped with rare-earth elements like ytterbium. This high-speed fiber laser cutting machine is ideal for cutting metals, including stainless steel, aluminum, and brass, with high precision. Fiber lasers offer faster cutting speeds, lower operational costs, and excellent energy efficiency compared to traditional laser systems.

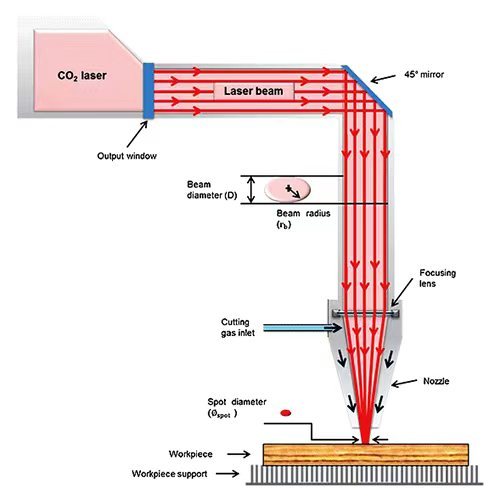

What is a CO₂ Laser Cutter?

Key Differences Between Fiber and CO₂ Laser Cutters

Cutting Speed and Precision

Operational Costs and Efficiency

Material Compatibility

| Features | CO₂ laser cutting machine | |

| Applicable materials | Mainly used for non-metal, can cut thin metal | Mainly used for metal cutting |

| Wavelength | 10.6μm (suitable for non-metal) | 1.06μm (suitable for metal) |

| Cutting quality | Smooth cut, suitable for fine engraving | Higher metal cutting efficiency |

Equipment cost | Relatively low | Higher price, low maintenance cost |

Energy consumption | Relatively high | More energy-efficient |

Application areas | Widely used in advertising, clothing, packaging, woodworking, etc. | Mainly used in metal processing, automobile, aviation and other industries |