Modern manufacturing requires different types of press brakes to meet a wide range of material, thickness, and accuracy requirements. Understanding the options will help you choose the right brake press machine for your shop.

1. Mechanical Press Brake

One of the earliest designs, a mechanical press brake uses a flywheel and clutch system to deliver force.

- Advantages: High speed, reliable for repetitive tasks.

- Limitations: Less flexible, limited precision compared to hydraulic or CNC machines.

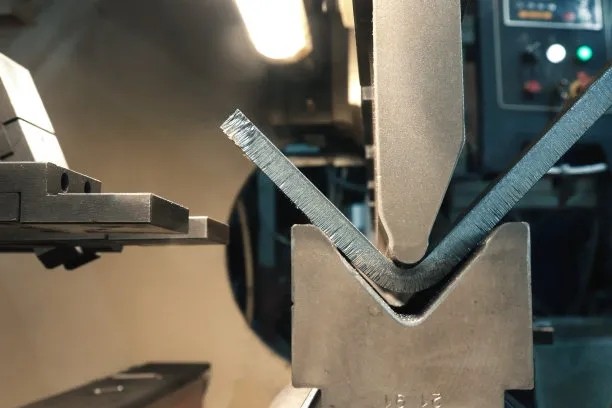

Hydraulic systems provide smooth, powerful motion, making them ideal for thicker materials.

- Advantages: High tonnage capacity, precise control.

- Applications: Widely used in construction, heavy machinery, and large-scale metal fabrication.

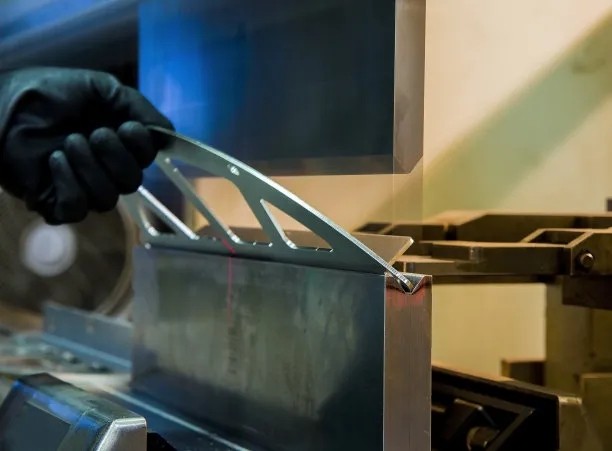

The most advanced type, CNC press brakes integrate computer numerical control for highly accurate and complex bends.

- Advantages: Automation, programmable backgauges, multi-axis control.

- Applications: Aerospace, electronics, precision engineering, high-volume production.

4. Aluminum Press Brake

Specially designed for lighter materials like aluminum, these brakes optimize for speed and delicate bending without damaging softer metals.

5. Hand Press Brake & Small Press Brakes

Compact, manual options designed for workshops or small-scale production.

- Advantages: Low cost, portable, easy to use.

- Limitations: Limited tonnage and bending length.

Summary of Types

From mechanical press brakes for simple repetitive tasks, to CNC automated metal brakes for high-precision work, the type you choose depends on your production needs, material thickness, and budget.