Before making any bends, a press brake operator must know how to properly set up the machine. Correct setup ensures both safety and precision.

1. Choosing the Right Tooling

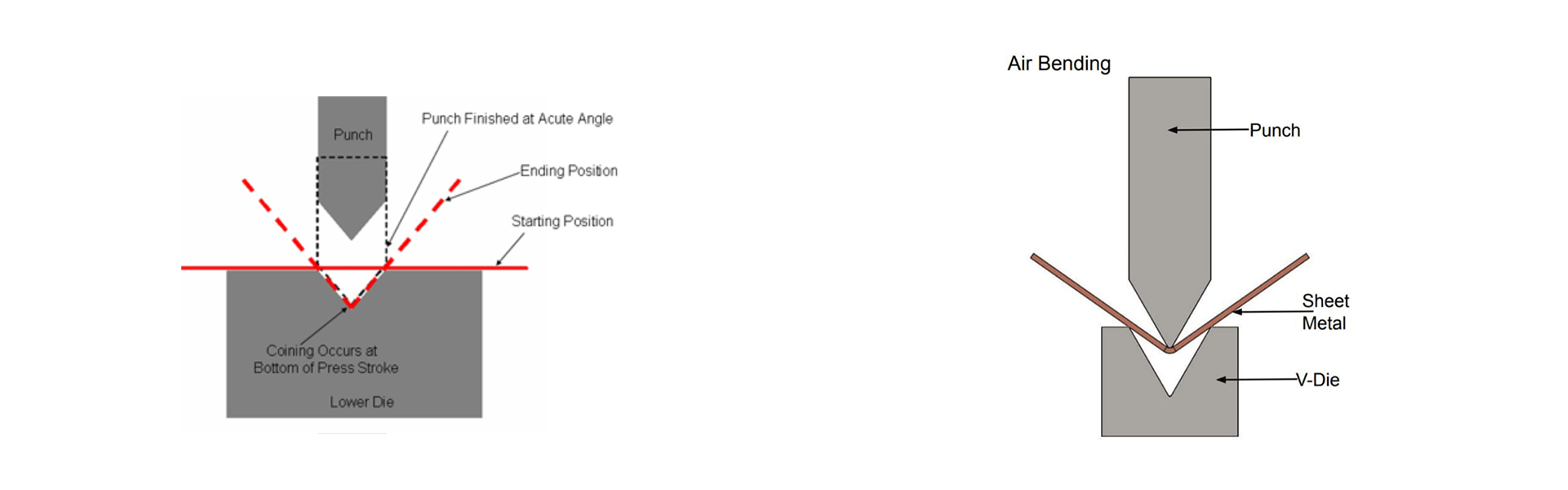

- Punch and die selection: Choose the punch and die according to the material type, thickness, and required bend angle.

- Check for wear or damage: Inspect tooling for cracks, dents, or deformities. Replace if necessary.

- Secure tooling properly: Use clamps or hydraulic clamping systems to fix the punch and die on the press brake bed.

2. Aligning Tooling

- Ensure that the upper punch and lower die are perfectly aligned. Misalignment can cause inaccurate bends and damage the tooling.

- Adjust the spacing to match the workpiece thickness. Beginners can use a feeler gauge or spacer to set the initial gap.

3. Setting Up the Back Gauge

- The back gauge ensures precise positioning of the sheet metal for repeatable bends.

- Adjust the back gauge according to the bend length and position of the workpiece.

- Beginners should start with simple adjustments and always verify measurements with a ruler or caliper before bending.

4. Pre-Operation Checks

- Check hydraulic oil level and inspect hoses for leaks.

- Verify that the emergency stop and light curtains are functioning.

- Ensure the work area is clean and free of obstacles.

Proper setup is the foundation of safe and accurate press brake operation. Beginners who master these basics can avoid errors and produce consistent, high-quality bends.