(1) Working principle of laser engraving

Laser engraving machines convert design patterns into permanent marks through laser beams. Their working principle is based on the sublimation process in which the laser beam vaporizes the specified area of the part. They can directly convert metal from solid to gas, leaving high-contrast modifications on the surface of the material, and realize the engraving of barcodes, logos, serial numbers, etc.

(2) Type selection of laser engraving machines

CO₂ laser engraving machine: It is the best choice for engraving wooden materials such as plywood and wood. It emits infrared radiation with a wavelength of about 10.6 microns, and the optimal laser power range is 40W to 300W. It is cost-effective, easy to set up, and versatile, suitable for complex and detailed designs, whether it is industrial application or commodity processing.

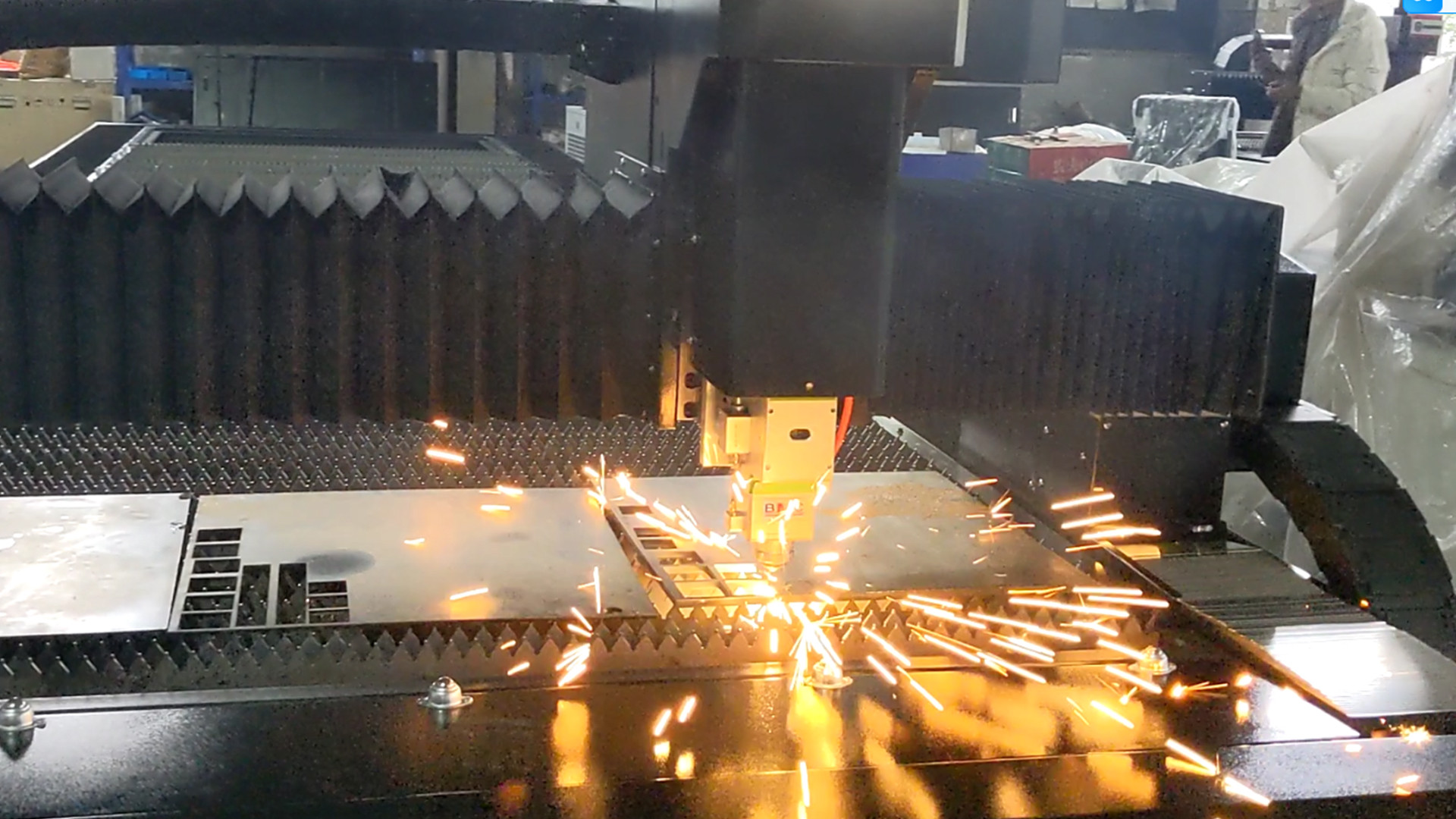

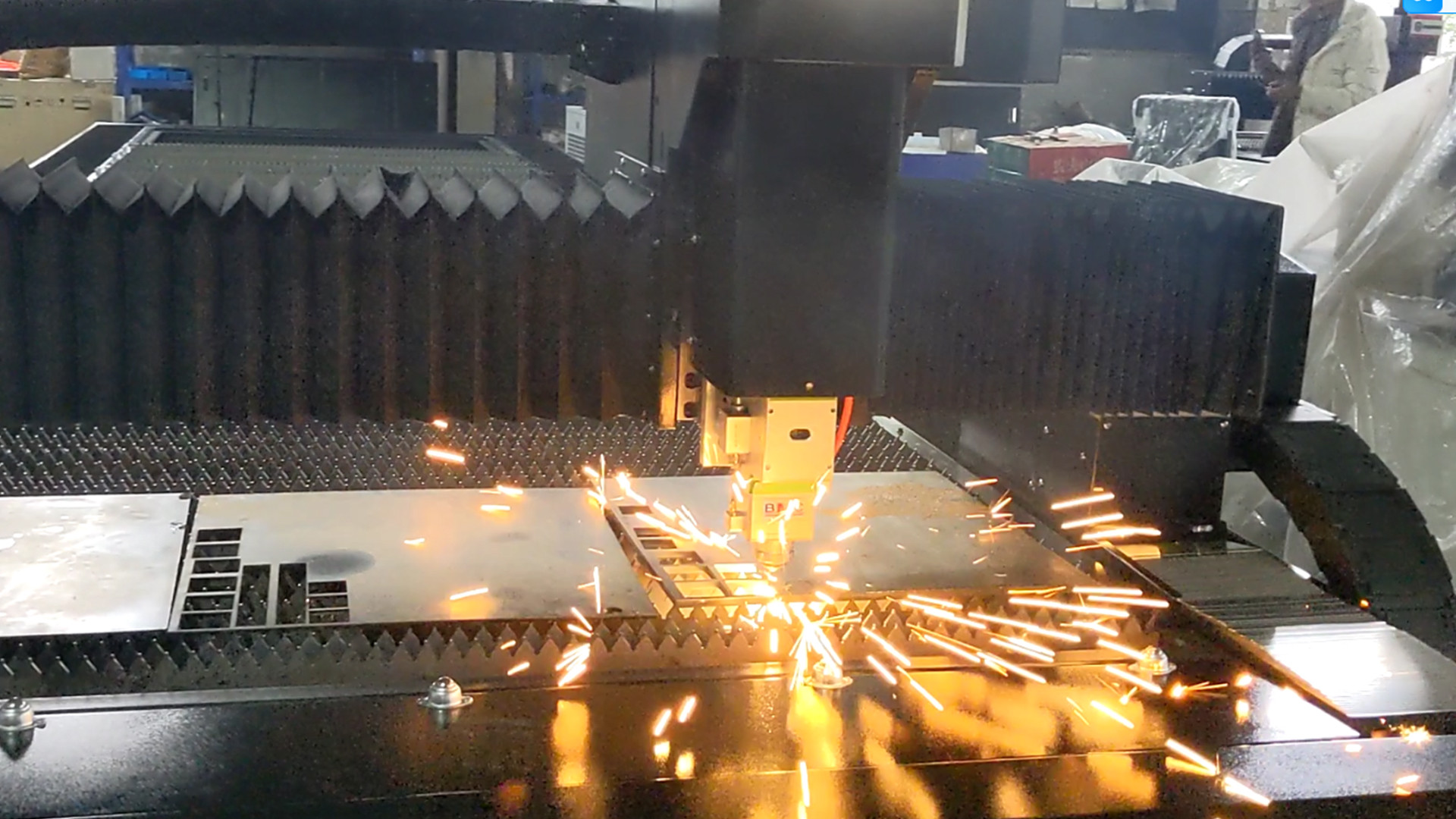

Fiber laser engraving machine: It is the king of metal engraving, especially suitable for metal materials such as carbon steel, stainless steel, aluminum, copper, and precious metals. It is a solid-state laser with a small focal diameter and high intensity, and the optical power is usually 2000 to 4000 watts. Its operating wavelength is 1064 nanometers, which can mark a variety of materials. It has excellent performance in industrial applications and has the advantages of safety, sustainability, and environmental protection. However, the initial cost is relatively high.

(3) Material considerations for laser engraving

Metal: Pure iron, steel and other metals are suitable for fiber laser engraving machines, and its 1064 nanometer wavelength can effectively mark metals. However, the higher the thermal conductivity and reflectivity of the material, the more difficult it is to engrave. For example, aluminum has strong thermal conductivity, so you need to be careful when engraving. Fiber lasers of different powers are suitable for different metal processing needs. For example, 50W fiber laser engraving machines are suitable for processing metals with high thermal conductivity and reflectivity, while A20W fiber lasers are suitable for metal marking and photoetching.

Plastics: UV laser marking machines are ideal for engraving plastics. Its 355 nanometer wavelength can produce smooth marks on plastics through photochemical reactions, avoiding soot and burrs caused by heat pressing. In addition, 3W UV machines or 20W, 30W fiber lasers can also achieve high-precision marking on plastics, and ComMarker fiber lasers can also form colored marks on plastics.

(4) Safety and cost of laser engraving

Operational safety precautions: Although laser engraving is powerful, it can be dangerous if used improperly. The laser beam is high-intensity and invisible, which can cause serious burns and eye damage, so be sure to wear laser goggles when operating. Laser engraving machines may also cause fires, so they need to be equipped with fire extinguishers; toxic fumes are emitted during operation, and a smoke exhaust system should be installed. At the same time, pay attention to the characteristics of the engraving material, read the product manual, keep a safe distance, seek help when moving the machine, and disconnect the power supply when cleaning and repairing.

Total investment and operating costs: The cost of laser engraving depends on many factors, such as laser power, wavelength, material type, and engraving machine type. CO₂ laser engraving machines have a wide price range, ranging from $150 for home use to $500,000 for industrial-grade machines, and their maintenance costs include lens and nozzle alignment, filter replacement, etc. Fiber laser engraving machines are relatively expensive, with the cost of 20W-60W ranging from $3,000 to $10,000, and the price of industrial-grade ones can exceed $1 million. In addition, the engraving material and the requirements for the engraving effect will also affect the overall cost.

Laser cutting and engraving technology, with its unique charm and excellent performance, has set off a revolution in precision processing in the manufacturing industry. Whether it is the pursuit of high-precision metal processing or the creative laser engraving, they have brought us unlimited possibilities. When choosing and using these technologies, fully understanding their processes, types, advantages and disadvantages, as well as safety and cost knowledge will help us better play their advantages and create better quality and exquisite products.