Fiber Laser Cutting Thickness: How Thick Can Fiber Laser Cut Different Metals

What is a Fiber Laser Cutting Machine?

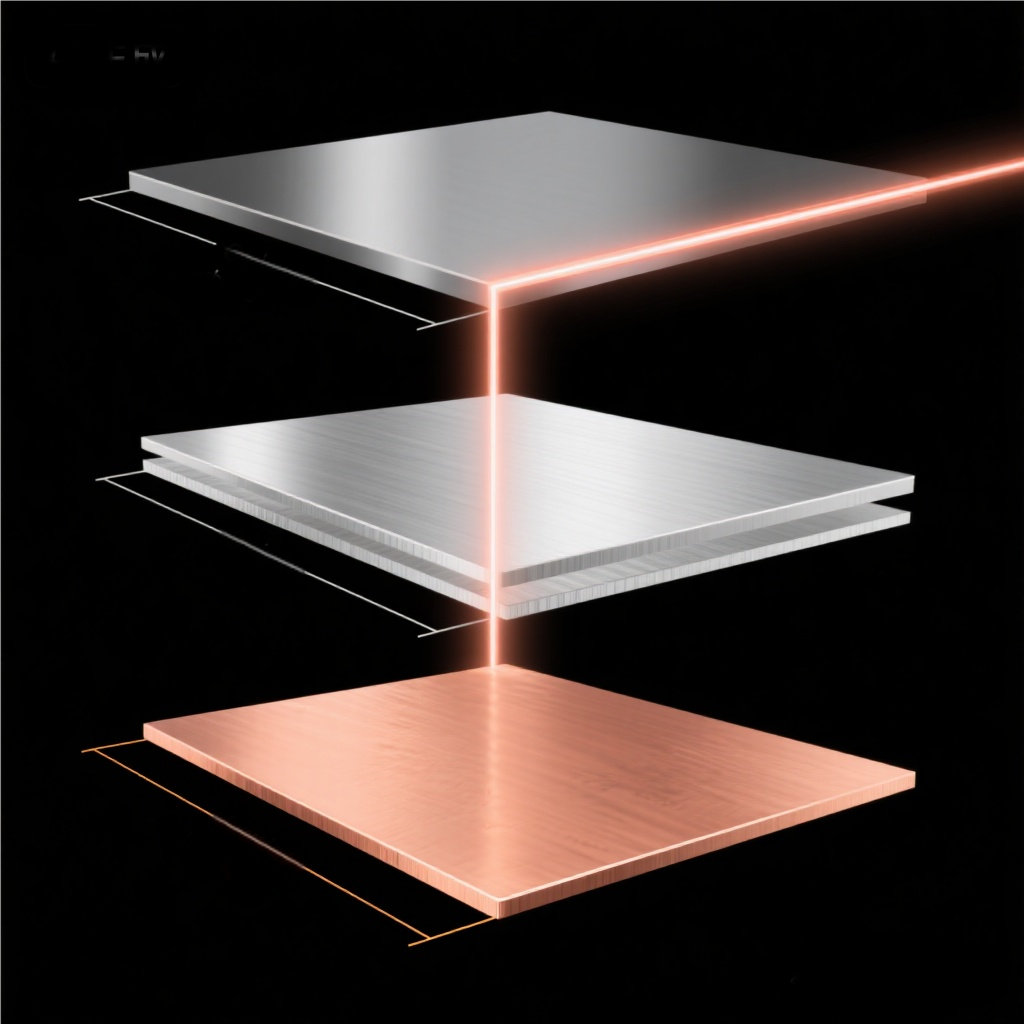

How Thick Can a Fiber Laser Cut Different Metals?

| Laser Power (W) | Material | Maximum Cutting Thickness (mm) | Maximum Cutting Thickness (in) |

| 500 | Carbon Steel | 6 | 0.24 |

| 500 | Stainless Steel | 3 | 0.12 |

| 500 | Aluminum | 2 | 0.08 |

500 | Copper | 2 | 0.08 |

1000 | Carbon Steel | 10 | 0.39 |

1000 | Stainless Steel | 5 | 0.20 |

1000 | Aluminum | 3 | 0.12 |

1000 | Copper | 3 | 0.12 |

2000 | Carbon Steel | 20 | 0.79 |

2000 | Stainless Steel | 8 | 0.31 |

2000 | Aluminum | 6 | 0.24 |

2000 | Copper | 4 | 0.16 |

4000 | Carbon Steel | 30 | 1.18 |

4000 | Stainless Steel | 12 | 0.47 |

4000 | Aluminum | 10 | 0.39 |

4000 | Copper | 6 | 0.24 |

Key Factors Affecting Cutting Thickness

Laser Power

Material Properties

Cutting Speed

Focus and Lens Quality

Nozzle and Assist Gas

Fiber Laser for Engraving vs. Cutting

| Application | Focus | Laser Power | Material Thickness |

| Cutting | Deep penetration | Medium to high | Thin to thick metal sheets |

| Engraving | Surface marking | Low to medium | Thin metals, plastics, composites |

Fiber laser engraving allows detailed designs on metals and non-metals, while cutting focuses on separating materials. Machines labeled as fiber laser for engraving or laser for engraving machine are optimized for high-precision surface work rather than through-cutting thick plates.