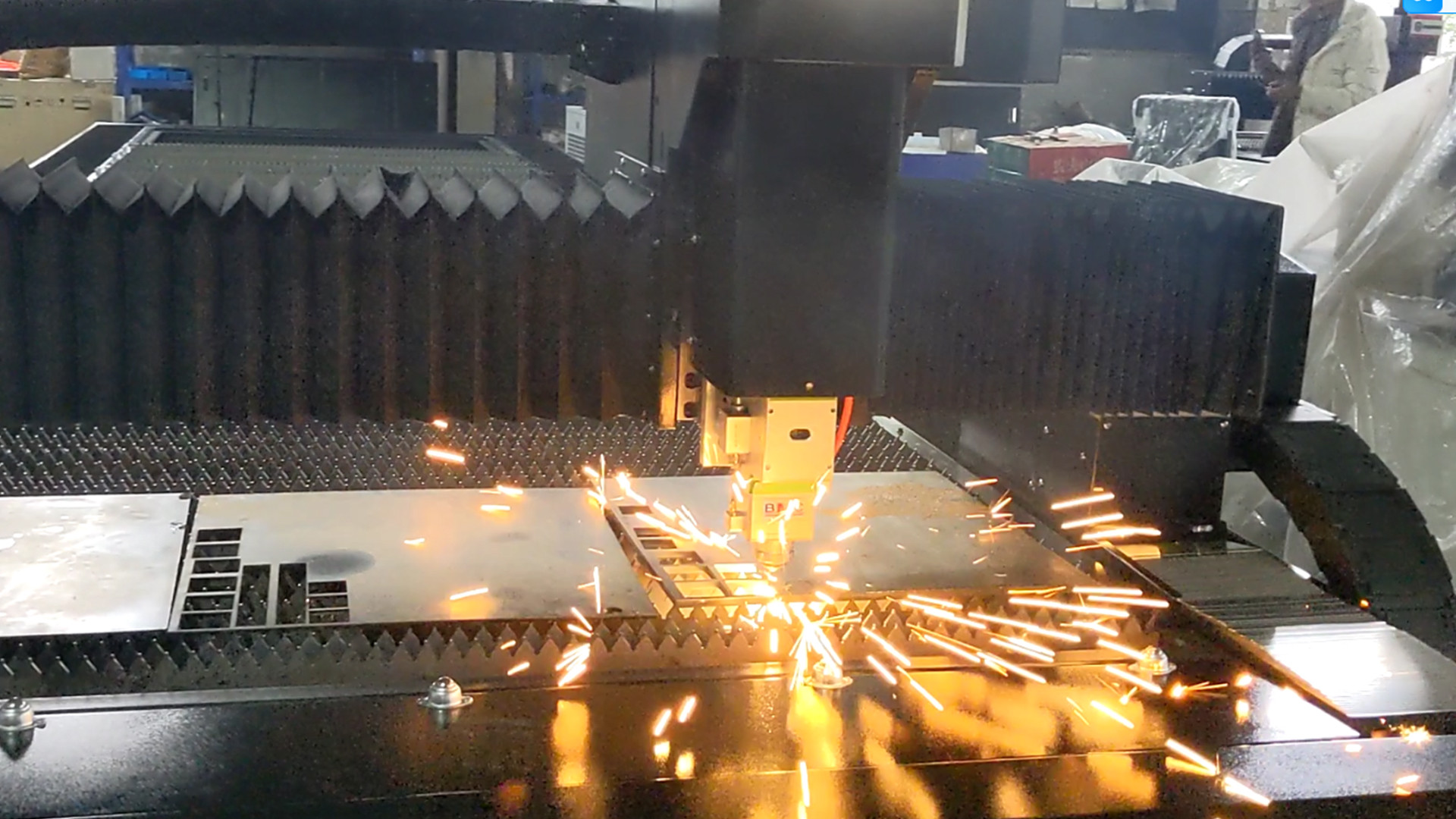

Selecting the right CNC laser cutting machine for steel is crucial for achieving high productivity, precision, and cost-effectiveness. With various models and laser technologies available, manufacturers must carefully evaluate their production needs before making an investment.

Key Factors to Consider

1. Material Type and Thickness

- Thin Sheets (≤ 12mm): Fiber lasers are more efficient and cost-effective.

- Medium to Thick Plates (12–30mm): Both fiber and CO₂ lasers can be considered, but fiber lasers provide faster cutting and better energy efficiency.

- Reflective Metals (copper, brass, aluminum): Fiber lasers are the superior choice due to their absorption efficiency.

2. Cutting Speed and Precision

- For industries that demand fast production cycles (e.g., automotive, appliance manufacturing), fiber lasers provide unmatched speed.

- For projects that prioritize edge quality and finish, cutting parameters must be tuned carefully.

3. Production Volume

- High-Volume Manufacturing: Automation features such as automatic loading/unloading systems can significantly boost efficiency.

- Small to Medium Workshops: Look for versatile machines with customizable bed sizes and power levels.

4. Operational Costs

- Fiber lasers typically require less maintenance and consume less power, making them a better long-term investment.

- CO₂ lasers often involve higher consumables and upkeep.

5. Software and Integration

- Modern CNC laser cutting machines integrate with CAD/CAM software, enabling precise, complex cutting paths.

- Look for user-friendly control systems that reduce the operator’s learning curve.

---

Why Choose RONGWIN Laser Cutting Machines?

At RONGWIN, we understand that every manufacturer has unique needs. Our fiber laser cutting machines for steel are designed with precision, efficiency, and versatility in mind:

- ✅ Wide Power Range: From 3kW up to 12kW, suitable for both thin sheet and thick plate cutting.

- ✅ Advanced CNC Control System: Ensures accuracy and smooth operation with minimal operator training required.

- ✅ Automation Ready: Options for auto-focus laser heads, loading/unloading systems, and intelligent nesting software for material optimization.

- ✅ Cost-Effective Performance: Engineered for low operating costs and high cutting speeds, maximizing ROI.

- ✅ Strong After-Sales Support: Technical training, installation guidance, and 24/7 service ensure long-term reliability.

With RONGWIN CNC laser machines, customers gain the flexibility to handle various steel thicknesses and production scales—whether it’s precision parts manufacturing or large-scale industrial fabrication.