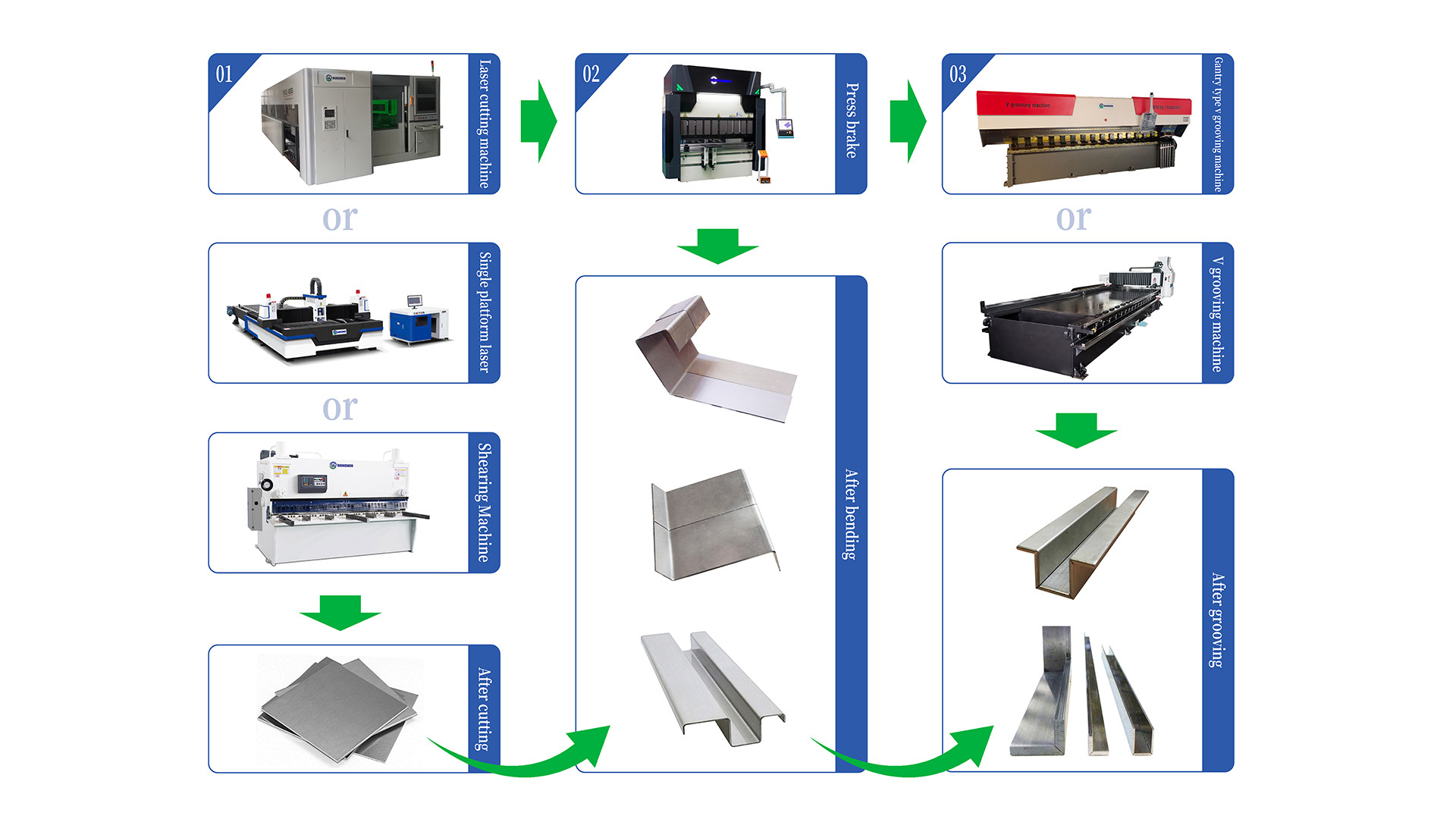

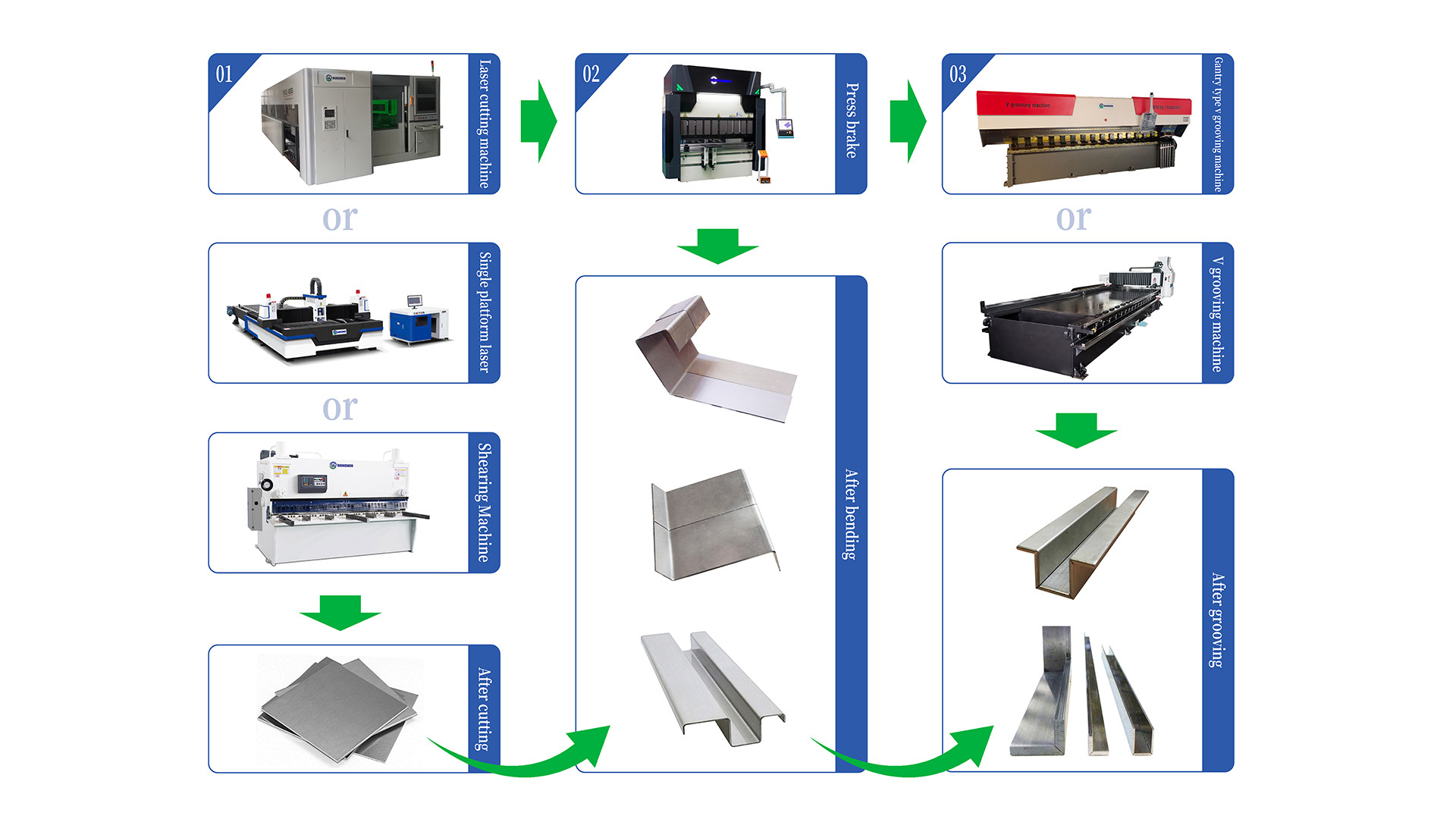

Core of the solution: precise coordination of three major processesLaser cutting machine - the basis for precise shaping:

Role: The first step of the solution, responsible for accurately cutting metal sheets (stainless steel, carbon steel, aluminum plates, etc.) into the required flat contours.

Advantages: No contact processing, no tool wear, can easily achieve complex shapes, fine holes (such as mounting holes, heat dissipation holes), and engraving marks. High precision (±0.1mm or even higher) lays a solid foundation for subsequent processes. Fast speed and high material utilization.

Value in this solution: Provide accurate blanks to ensure that the slit position and bending line benchmarks are accurate.

Grooving Machine - The key to complex bending and assembly:

Role: Accurately process V-shaped, U-shaped or other specific grooves at the bending line or in areas that require special forming.

Advantages: Remove some material, significantly reduce the force required for bending, reduce the bending radius, and avoid cracks or deformation on the sheet surface caused by extrusion (especially on thick plates or hard materials). It is the core process for achieving "zero radius" bending, hinge structures, special curling or assembly buckles.

Value in this solution: Create ideal conditions for subsequent high-precision bending, which is an indispensable link in achieving complex geometric shapes (such as boxes, parts with flanges or inward buckles), and improve the strength and aesthetics of the workpiece.

Bending machine - giving workpieces three-dimensional life:

Role: The final forming step of the solution, using precision molds to bend the slotted flat sheet into a preset three-dimensional angle and shape.

Advantages: Thanks to the slotting process, the bending process is smoother and more precise, with less springback and extremely high angle consistency. Multiple bends can be completed to form various three-dimensional structures such as boxes, brackets, and shells.

Value in this solution: Efficiently and high-quality conversion of precisely cut and slotted flat parts into the final required three-dimensional workpiece.